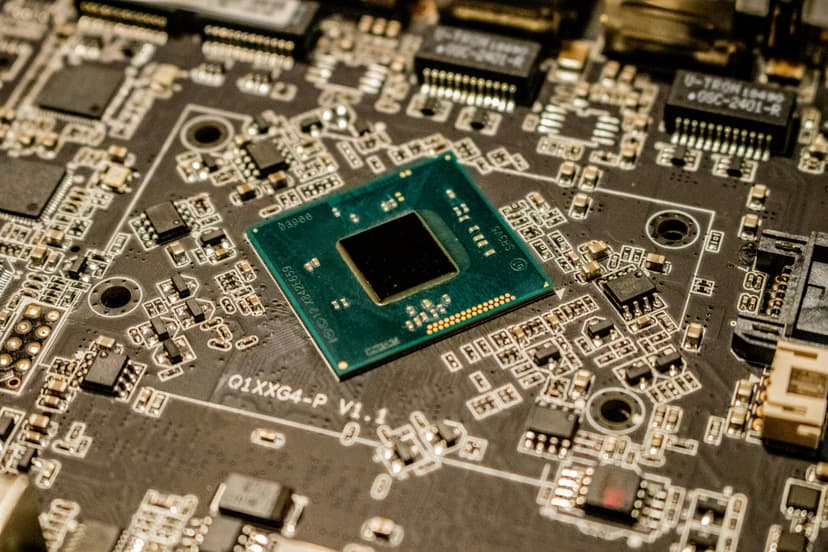

Semiconductor Industry

Vacuum brazing is essential in the semiconductor industry, where ultra-clean, high-precision bonding is required for the fabrication of advanced electronic components. It is widely used in the production of heat sinks, sensor housings, wafer processing tools, and vacuum chamber assemblies. The process enables the joining of dissimilar metals and complex structures without introducing flux or contaminants, making it ideal for maintaining the ultra-high vacuum and purity levels demanded in semiconductor environments. Vacuum brazing ensures superior thermal conductivity, structural integrity, and leak-tight sealing—critical for temperature-sensitive and high-performance semiconductor devices.

Articles

Graphite and Copper Welding for High-Performance Electrical and Thermal Applications

Graphite and copper combinations are widely used in electrical and thermal management systems due to their complementary properties.

Vacuum brazing of graphite and copper

Vacuum brazing of graphite and copper is a specialized joining process used in high-temperature, high-thermal-conductivity applications such as semiconductor equipment, heat sinks, EDM components, and aerospace thermal assemblies.

AMB Ceramic Copper-Clad Laminate Vacuum Brazing Finished Products for Power Electronics

AMB ceramic copper-clad laminates are widely used as high-performance substrates in power electronics due to their excellent thermal conductivity, electrical insulation, and mechanical strength.

Finished Copper–Silver Products for Electrical and Power Equipment Applications

Copper provides excellent electrical and thermal conductivity at an economical cost, while silver enhances surface conductivity, contact reliability, and resistance to oxidation.

Vacuum Brazing of AMB (Active Metal Brazing) Ceramic Copper Clad Laminate

Vacuum brazing of AMB (Active Metal Brazing) ceramic copper clad laminate is a critical process used in the production of high-performance power electronic substrates.