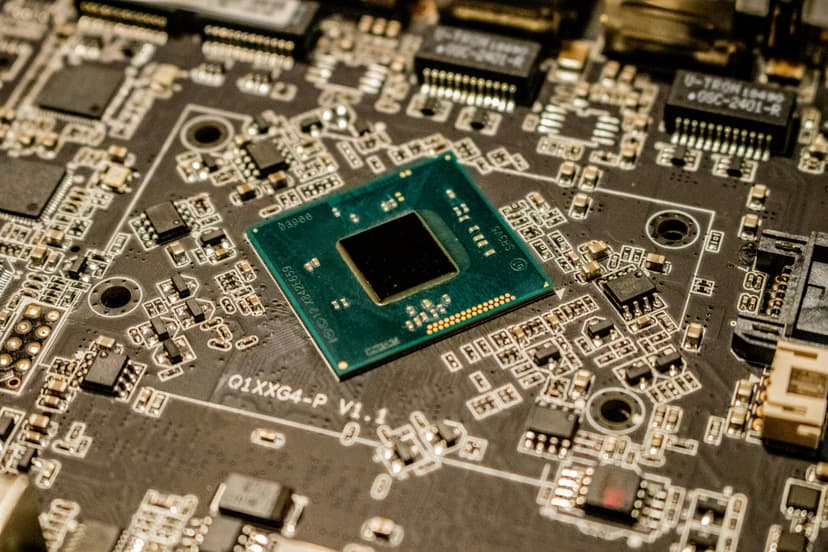

Semiconductor Industry

Vacuum brazing is essential in the semiconductor industry, where ultra-clean, high-precision bonding is required for the fabrication of advanced electronic components. It is widely used in the production of heat sinks, sensor housings, wafer processing tools, and vacuum chamber assemblies. The process enables the joining of dissimilar metals and complex structures without introducing flux or contaminants, making it ideal for maintaining the ultra-high vacuum and purity levels demanded in semiconductor environments. Vacuum brazing ensures superior thermal conductivity, structural integrity, and leak-tight sealing—critical for temperature-sensitive and high-performance semiconductor devices.

Articles

DT4C Electrical Pure Iron Heat Treatment for Coercivity Reduction and Demagnetization

DT4C electrical pure iron is a high-purity soft magnetic material widely used in electromagnetic devices, sensors, and precision instruments. To achieve its optimal magnetic performance, the material must undergo a specialized heat treatment process designed to remove wire drawing stress.

Enhancing Magnetic Performance for Semiconductor Applications

The DT4C electrical pure iron is widely used for such applications due to its high magnetic permeability and low coercive force — but only when processed under optimal thermal conditions.

Aluminium Ultra-Thin Water Cooling Plate – Vacuum Brazed Finished Product

The Aluminium Ultra-Thin Water Cooling Plate manufactured through vacuum brazing technology represents a breakthrough in advanced thermal management solutions. Its ultra-thin structure provides efficient space utilization while ensuring superior heat dissipation performance.

Welding of Kovar Alloy and Alumina Ceramics – Building the Backbone of Reliable Electronics

In the electronics industry, precision and reliability are non-negotiable. Many advanced devices, from sensors to microelectronics, require materials with both thermal stability and hermetic sealing to protect sensitive components from environmental damage.

Copper Welding Solutions

Copper is widely used across industries due to its excellent thermal and electrical conductivity, making it an essential material in applications such as electronics, automotive components, energy systems, and medical devices.