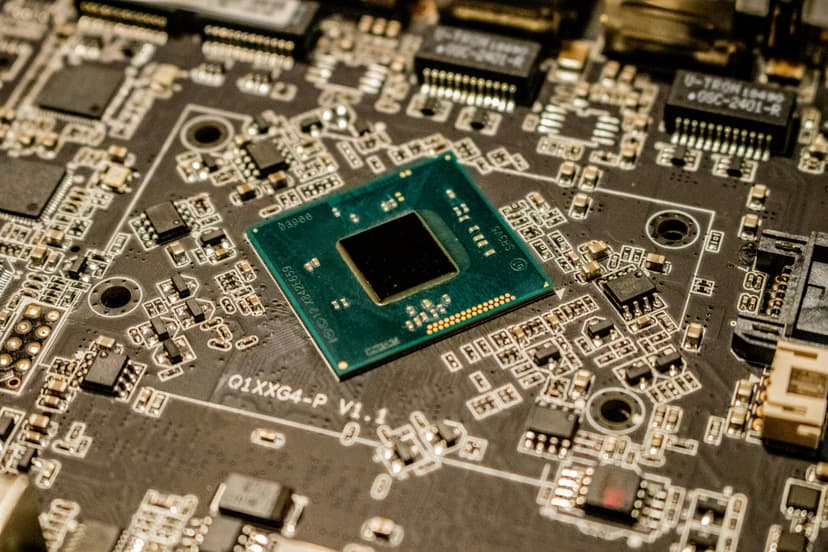

Semiconductor Industry

Vacuum brazing is essential in the semiconductor industry, where ultra-clean, high-precision bonding is required for the fabrication of advanced electronic components. It is widely used in the production of heat sinks, sensor housings, wafer processing tools, and vacuum chamber assemblies. The process enables the joining of dissimilar metals and complex structures without introducing flux or contaminants, making it ideal for maintaining the ultra-high vacuum and purity levels demanded in semiconductor environments. Vacuum brazing ensures superior thermal conductivity, structural integrity, and leak-tight sealing—critical for temperature-sensitive and high-performance semiconductor devices.

Articles

Vacuum Brazing of Silicon Nitride-Tungsten Electrode Silver Contacts for Power Electronics and Semiconductor Applications

Discover how vacuum brazing of silicon nitride–tungsten electrode silver contacts ensures high-reliability power electronics and semiconductor components. Learn how Normantherm’s vacuum furnaces help Indian manufacturers achieve precise, contamination-free joints with over 15 years of expertise.

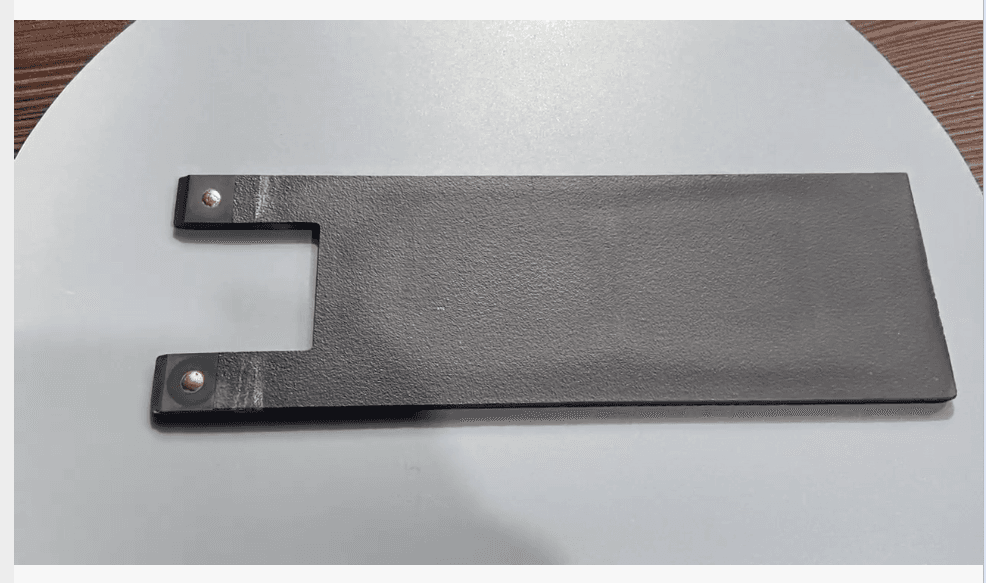

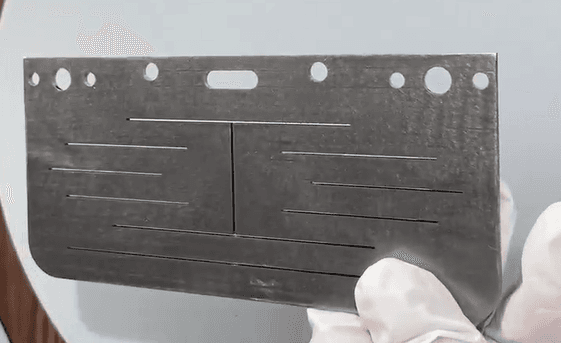

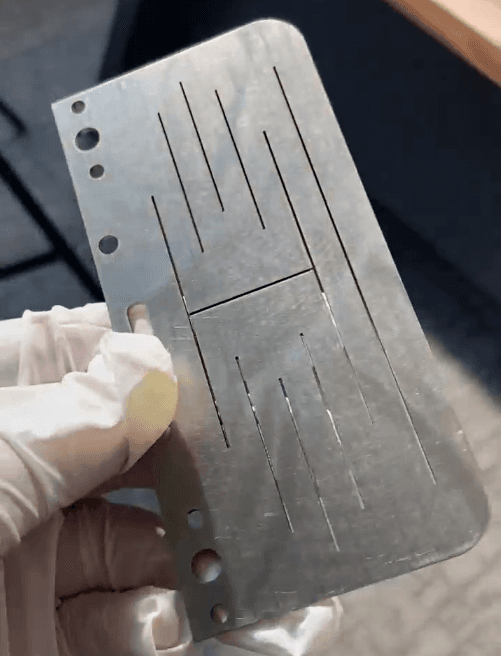

Vacuum Brazing of Ultra-Thin Titanium Alloy Microchannel Water Coolers for Semiconductor Applications

Vacuum brazing is a key manufacturing technology for producing ultra-thin titanium alloy microchannel water coolers used in advanced semiconductor thermal management systems.

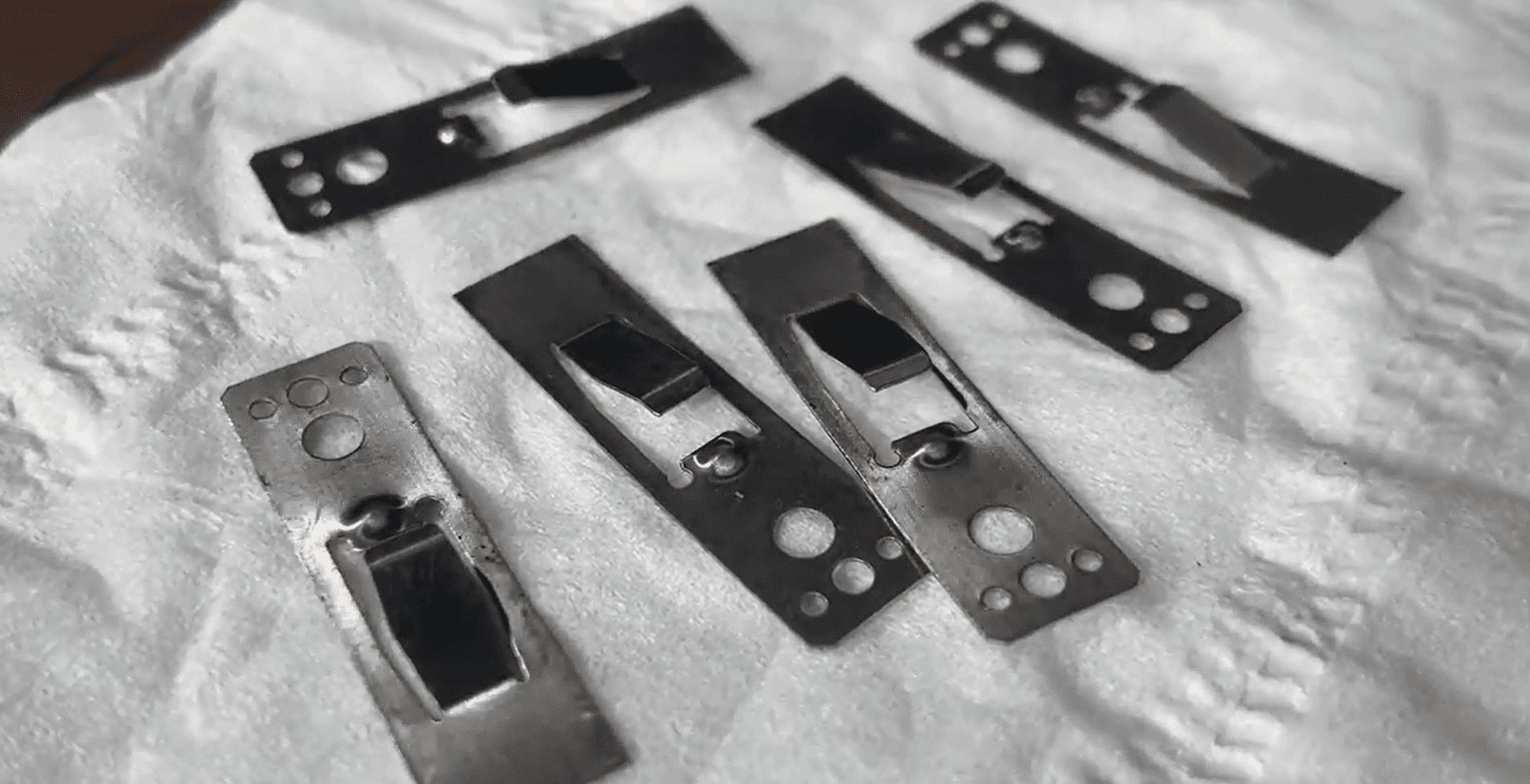

Vacuum Heat Treatment of Nickel-Beryllium Alloy Springs for Electronics & Semiconductor Applications

Explore vacuum heat treatment of nickel-beryllium alloy springs in electronics & semiconductors with Normantherm furnaces for Indian manufacturers.

Vacuum Brazed Ultra-Thin Titanium Alloy Microchannel Water Coolers for Semiconductor Applications

Ultra-thin titanium alloy microchannel water coolers vacuum brazed using Normantherm furnaces for high-power semiconductor thermal management in India.

Ultra-Thin Titanium Alloy Microchannel Water Coolers for Semiconductor Applications

Thermal management is a critical factor in semiconductor manufacturing, where even minor temperature fluctuations can impact process stability and yield.