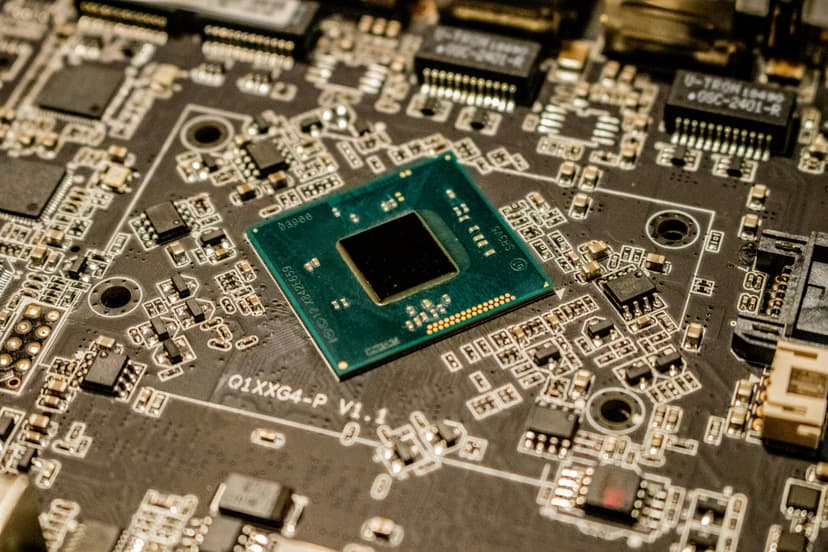

Semiconductor Industry

Vacuum brazing is essential in the semiconductor industry, where ultra-clean, high-precision bonding is required for the fabrication of advanced electronic components. It is widely used in the production of heat sinks, sensor housings, wafer processing tools, and vacuum chamber assemblies. The process enables the joining of dissimilar metals and complex structures without introducing flux or contaminants, making it ideal for maintaining the ultra-high vacuum and purity levels demanded in semiconductor environments. Vacuum brazing ensures superior thermal conductivity, structural integrity, and leak-tight sealing—critical for temperature-sensitive and high-performance semiconductor devices.

Articles

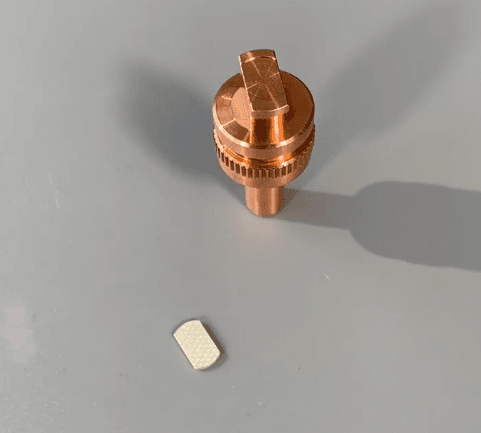

Vacuum Brazing of Copper and Silver for the Electronics Industry

Our recent project — the vacuum brazing of copper and silver — demonstrates our capability to deliver clean, high-strength, and oxidation-free welds essential for modern electronic manufacturing.

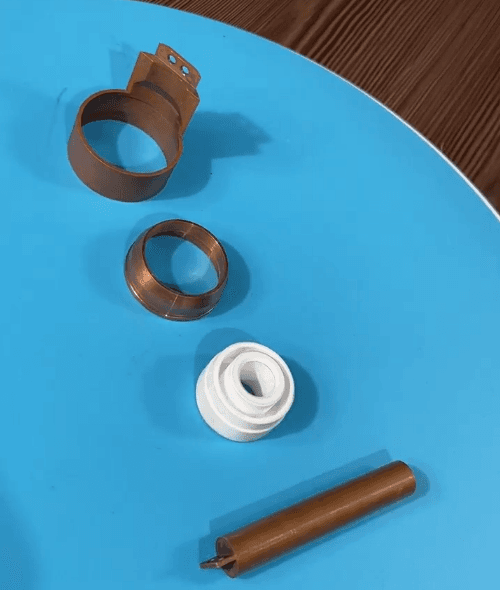

Ceramic and Copper Brazing — Precision Bonding for the Electronics Industry

In high-performance electronics, where heat dissipation and electrical insulation must coexist, ceramic-to-copper brazing plays a crucial role. The process joins two dissimilar materials — ceramics that offer excellent insulation and copper that provides superior thermal and electrical conductivity.

4J29 (Kovar Alloy) Heat Treatment for Semiconductor Packaging — Ensuring Dimensional Stability & Sealing Performance

The semiconductor industry demands materials that can withstand thermal cycling, vacuum environments, and hermetic sealing processes. One such critical material is 4J29 (also known as Kovar alloy) — a precision iron-nickel-cobalt alloy known for its low thermal expansion.

Vacuum Heat Treatment of 4J29 Iron-Nickel Alloy Sheet for Semiconductor Applications

4J29 iron-nickel alloy (Kovar) is a precision material used in the semiconductor and electronic packaging industry. Its thermal expansion closely matches borosilicate glass, enabling reliable glass-to-metal sealing for Integrated Circuit packages, sensors, relays, and hermetic connectors.

Heat Treatment of Brass

Brass heat treatment is an essential metallurgical process used to enhance the mechanical and structural properties of brass alloys, which are primarily composed of copper and zinc.