Aerospace Industry

Vacuum brazing is a vital process in the aerospace industry, where precision, strength, and reliability are non-negotiable. It is extensively used in the production of turbine blades, heat exchangers, fuel system components, jet engine parts, and structural assemblies that must withstand extreme temperatures and mechanical stress. The process enables the joining of dissimilar metals and intricate assemblies without the use of flux, eliminating the risk of contamination and ensuring the highest levels of cleanliness. This is crucial in aerospace applications, where even microscopic impurities can compromise performance or safety.

Articles

Vacuum Brazing of Stainless Steel Impeller – Finished Product

Vacuum brazing is an advanced and highly reliable process used in the manufacturing of stainless steel impeller finished products, commonly applied in pumps, compressors, turbines, and high-performance fluid handling systems.

Stainless Steel and Gold-Plated Stainless Steel Pins with Ceramic Vacuum Brazing

Ceramic vacuum brazing is an advanced joining technology used to bond stainless steel and gold-plated stainless steel pins with ceramic components in applications requiring high precision, electrical reliability, and long-term stability.

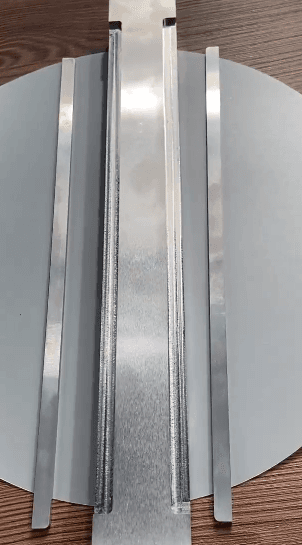

Mold Steel and Tungsten Steel Welding for High-Wear Applications

Mold steel and tungsten steel welding is a specialized joining process used to produce high-strength tooling components for demanding industrial environments.

Vacuum Brazing of CBN Cutting Tools

Cubic Boron Nitride (CBN) cutting tools are widely used in high-precision machining applications where extreme hardness, thermal stability, and wear resistance are required.

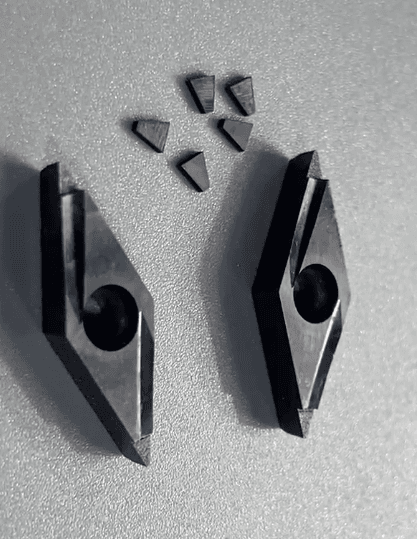

Vacuum Brazing of CR12MoV Tool Steel and Tungsten Carbide

Vacuum brazing is a proven high-performance joining process used to bond CR12MoV tool steel and tungsten carbide for demanding wear-resistant tooling applications.