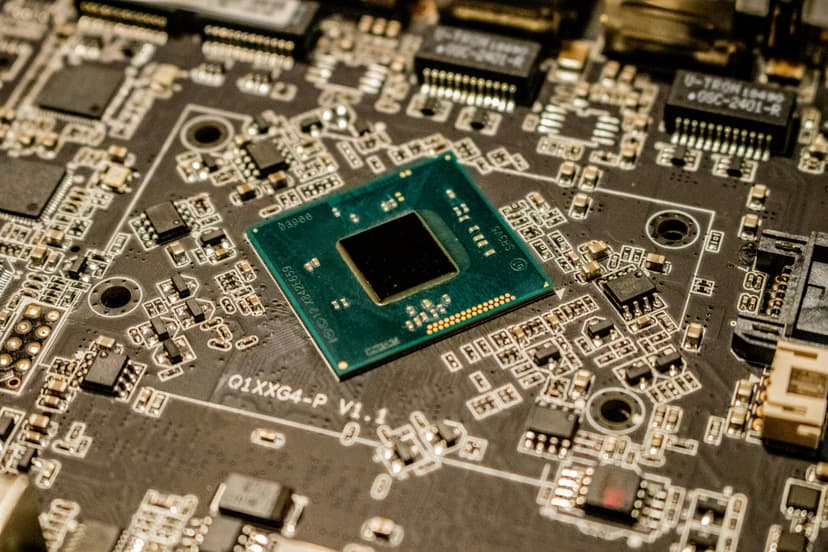

Semiconductor Industry

Vacuum brazing is essential in the semiconductor industry, where ultra-clean, high-precision bonding is required for the fabrication of advanced electronic components. It is widely used in the production of heat sinks, sensor housings, wafer processing tools, and vacuum chamber assemblies. The process enables the joining of dissimilar metals and complex structures without introducing flux or contaminants, making it ideal for maintaining the ultra-high vacuum and purity levels demanded in semiconductor environments. Vacuum brazing ensures superior thermal conductivity, structural integrity, and leak-tight sealing—critical for temperature-sensitive and high-performance semiconductor devices.

Articles

AMB Ceramic Copper-Clad Laminate Vacuum Brazing for High-Power Electronics

AMB (Active Metal Brazed) ceramic copper-clad laminates are among the most reliable materials used in high-power electronics. Their unique combination of ceramic insulation and copper conductivity makes them ideal for applications such as IGBT modules, EV inverters, high-efficiency power supplies.

Vacuum Brazing of 6061 Series Large Aluminium Cooled Plates

Vacuum brazing is the preferred method for manufacturing large 6061 series aluminum cooled plates, commonly used in high-power electronics, laser systems, battery cooling modules, and industrial thermal management equipment.

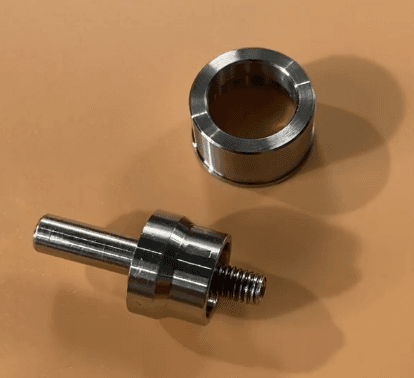

Ceramic Welding with Kovar/Titanium Alloy for Semiconductor Components

Ceramic-to-metal welding is a critical manufacturing process in the semiconductor industry, where components must withstand high temperatures, ultra-high vacuum, and long-term operational stress.

Vacuum Brazing of Kovar Alloy and Alumina Ceramics for India’s Electronics Industry

Explore vacuum brazing of Kovar alloy (Fe-Ni-Co) and alumina (Al₂O₃) ceramics for high-reliability electronics. Learn about processes, advantages, and Normantherm’s 15+ years expertise supporting India’s semiconductor and electronics industry.

Kovar Alloy Welding with Alumina Ceramics: A Critical Innovation for High-Reliability Electronics

Kovar alloy (Fe-Ni-Co) and alumina (Al₂O₃) ceramics are widely used in high-precision electronic components, especially where vacuum sealing, magnetic stability, and thermal expansion compatibility are essential.