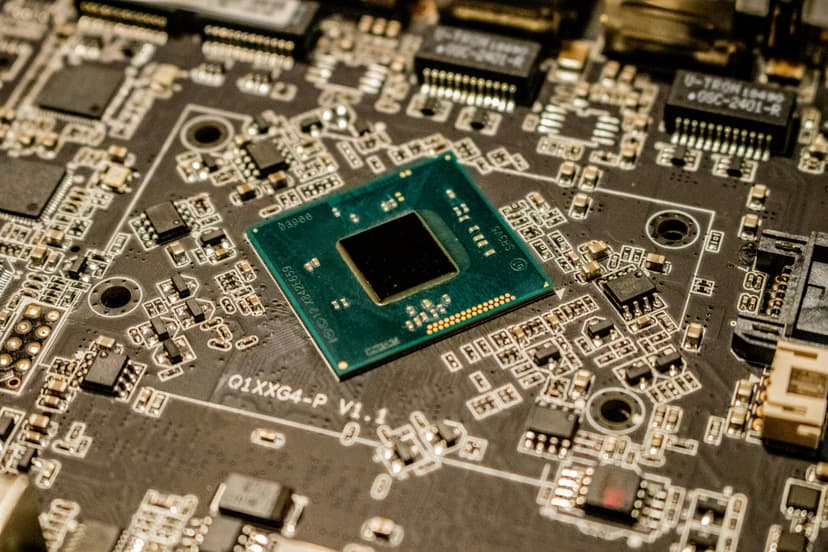

Semiconductor Industry

Vacuum brazing is essential in the semiconductor industry, where ultra-clean, high-precision bonding is required for the fabrication of advanced electronic components. It is widely used in the production of heat sinks, sensor housings, wafer processing tools, and vacuum chamber assemblies. The process enables the joining of dissimilar metals and complex structures without introducing flux or contaminants, making it ideal for maintaining the ultra-high vacuum and purity levels demanded in semiconductor environments. Vacuum brazing ensures superior thermal conductivity, structural integrity, and leak-tight sealing—critical for temperature-sensitive and high-performance semiconductor devices.

Articles

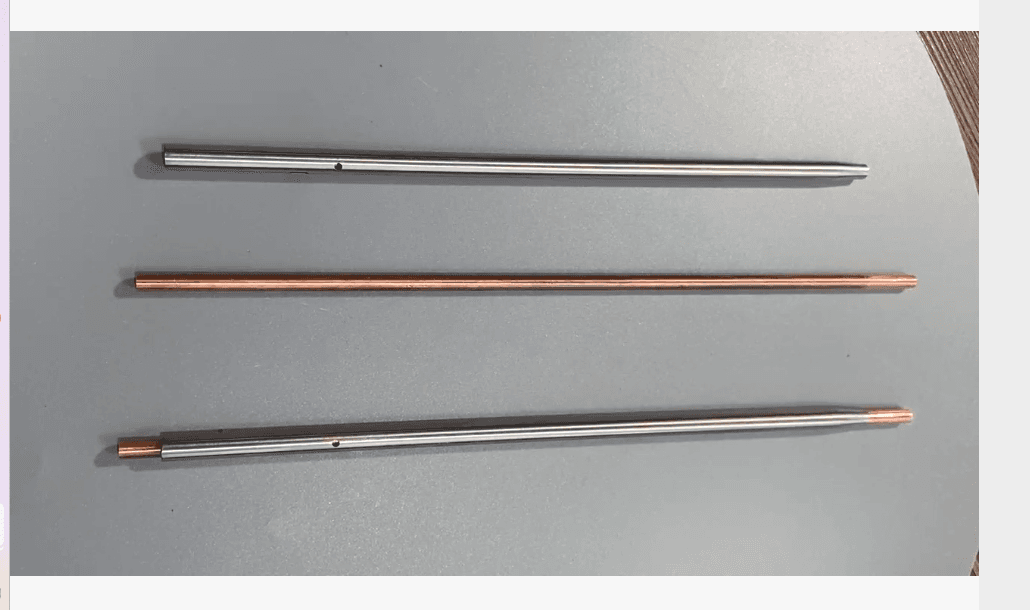

Vacuum Brazing of 304 Stainless Steel and Oxygen-Free Copper for Industrial Applications

The combination of 304 stainless steel and oxygen-free copper is widely used in industrial systems where corrosion resistance, mechanical strength, and high conductivity must coexist.

Vacuum Brazing of 304 Stainless Steel and Oxygen-Free Copper for Semiconductor Manufacturing

Discover how Normantherm vacuum furnaces help Indian manufacturers vacuum braze 304 stainless steel and oxygen-free copper with high precision, reliability, and optimal thermal performance.

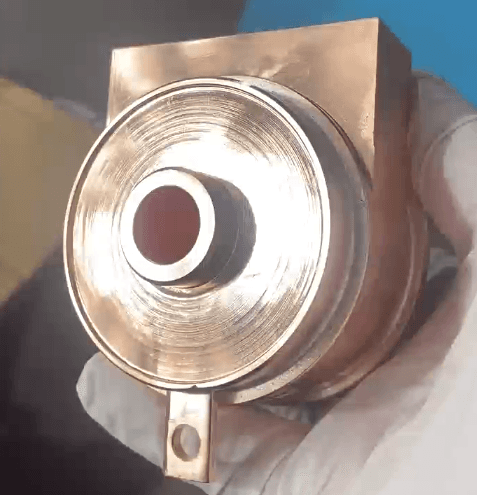

Oxygen-Free Copper Welded Finished Products for High-Conductivity Applications

Oxygen-free copper is a critical material in industries where electrical and thermal performance cannot be compromised. Its extremely low oxygen content ensures superior conductivity, making it ideal for power, electronics, and thermal management applications.

CBN Tool Welding Using Vacuum Brazing Technology

Cubic boron nitride (CBN) cutting tools are essential for high-precision machining of hardened steels and difficult-to-cut materials. The performance of these tools depends heavily on the quality of the bond between the CBN insert and the tool body.

Oxygen-Free Copper Welding for High-Performance Applications

Oxygen-free copper welding is a precision joining process used where maximum electrical conductivity and thermal efficiency are critical.