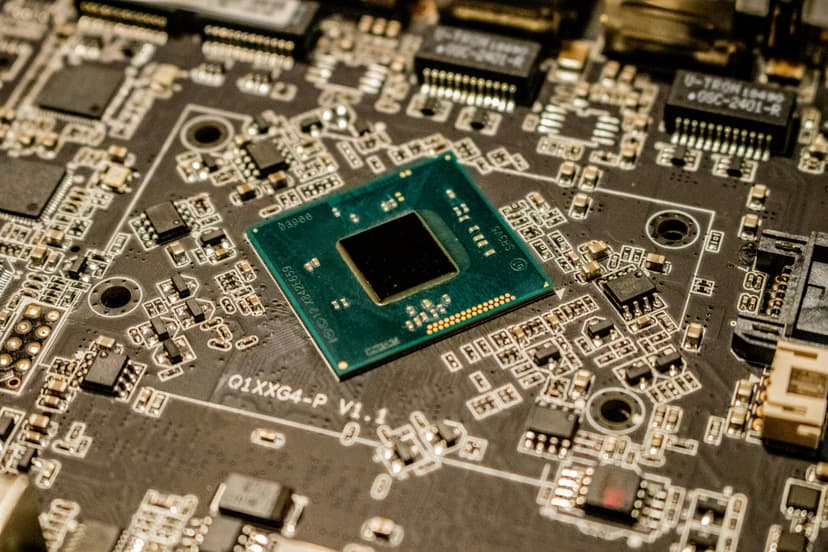

Semiconductor Industry

Vacuum brazing is essential in the semiconductor industry, where ultra-clean, high-precision bonding is required for the fabrication of advanced electronic components. It is widely used in the production of heat sinks, sensor housings, wafer processing tools, and vacuum chamber assemblies. The process enables the joining of dissimilar metals and complex structures without introducing flux or contaminants, making it ideal for maintaining the ultra-high vacuum and purity levels demanded in semiconductor environments. Vacuum brazing ensures superior thermal conductivity, structural integrity, and leak-tight sealing—critical for temperature-sensitive and high-performance semiconductor devices.

Articles

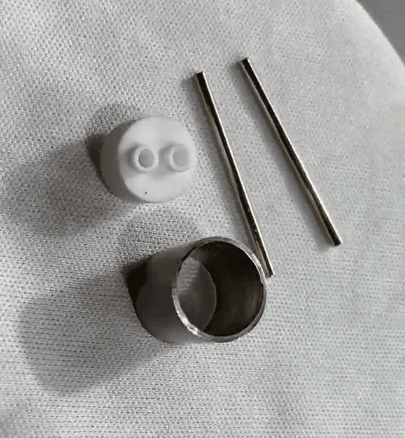

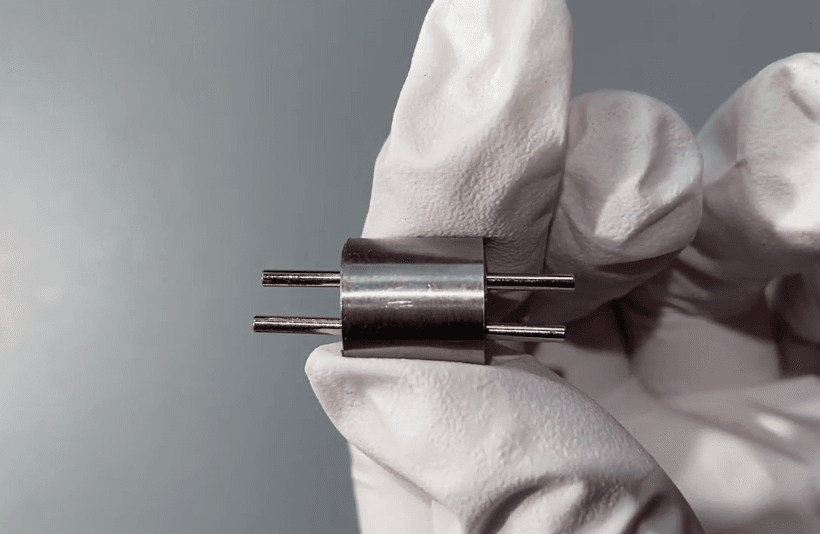

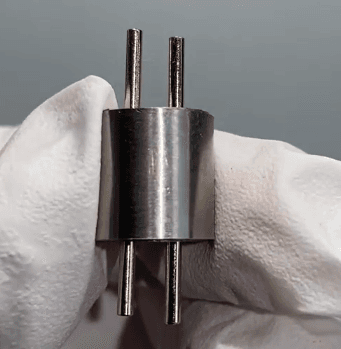

Before and After Welding PDC to Stainless Steel

This before and after comparison clearly shows the impact of precision welding when joining PDC Polycrystalline Diamond Compact to stainless steel.

Vacuum Brazing of Stainless Steel and Gold-Plated Pins with Ceramic for High-Reliability Electronic Components

Metal-to-ceramic joining is a critical manufacturing process in industries where electrical insulation, corrosion resistance, and hermetic sealing are essential.

Vacuum Brazing of Stainless Steel, Gold-Plated Pins and Ceramics for Electronics & Semiconductor Applications

Explore vacuum brazing of stainless steel, gold-plated pins, and ceramics for electronics & semiconductor manufacturing in India with Normantherm furnaces.

Ceramic Soldering of Stainless Steel and Gold-Plated Stainless Steel Pins for High-Reliability Components

Metal-to-ceramic assemblies are critical in industries where electrical insulation, corrosion resistance, and long-term reliability are essential.

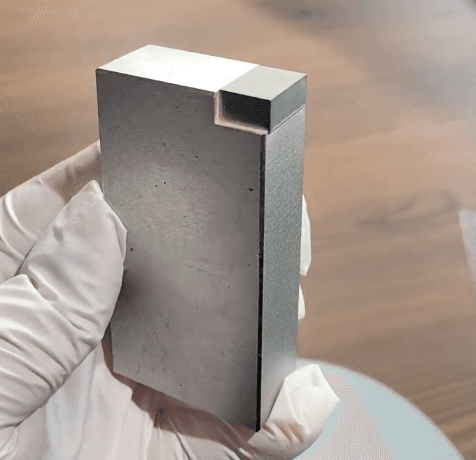

Finished Products Welded from Tungsten Steel and Mold Steel for High-Performance Tooling

Tooling and mold components operate under severe mechanical stress, abrasion, and thermal cycling. To achieve long service life and consistent performance, manufacturers often combine tungsten steel with mold steel in critical areas of finished products.