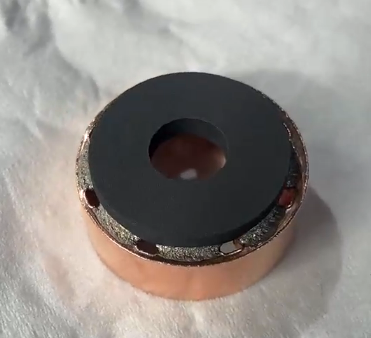

Graphite and Copper Welding for High-Performance Electrical and Thermal Applications

Graphite and copper combinations are widely used in electrical and thermal management systems due to their complementary properties. Graphite offers excellent thermal stability, low thermal expansion, and resistance to high temperatures, while copper provides outstanding electrical and thermal conductivity.

In India’s growing power, electronics, and industrial equipment sectors, demand for reliable graphite–copper finished products continues to increase.

Why Graphite and Copper Are Used Together

When properly joined, graphite and copper create components capable of operating under high current loads and elevated temperatures.

Key advantages include:

- High electrical conductivity

- Efficient heat dissipation

- Thermal stability at elevated temperatures

- Reduced thermal expansion mismatch in assemblies

- Long service life under continuous operation

These characteristics make graphite–copper components ideal for demanding electrical and thermal environments.

Challenges in Welding Graphite to Copper

Graphite and copper have significantly different physical and chemical properties, making conventional joining methods unreliable. Common challenges include:

- Poor wettability of graphite

- Oxidation at copper surfaces

- Weak interfacial bonding

- Thermal stress during cooling

Vacuum welding overcomes these challenges by providing a controlled environment for stable interfacial bonding.

Role of Vacuum Welding in Finished Product Quality

Vacuum welding ensures clean, oxide-free surfaces and precise thermal control, enabling strong and consistent bonding between graphite and copper.

Key benefits include:

- Improved interfacial bonding strength

- Reduced residual stress

- Clean joint surfaces without contamination

- Stable electrical and thermal performance

- Repeatable quality for industrial production

This process ensures that finished products meet performance and durability requirements.

Relevance to India’s Electrical and Thermal Management Industry

India’s power generation, electronics manufacturing, railways, and industrial machinery sectors rely on graphite–copper components for applications such as:

- Electrical contacts and current collectors

- Heat sinks and thermal spreaders

- Power transmission components

- Industrial electrical equipment

As these industries continue to expand, advanced welding technologies are critical to maintaining reliability and efficiency.

Normantherm’s Expertise in Graphite–Copper Welding

Normantherm designs and manufactures advanced vacuum welding furnaces optimized for dissimilar material joining, including graphite and copper. Our systems provide:

- High-vacuum, oxygen-free welding environments

- Precise temperature control for sensitive materials

- Strong and uniform joint formation

- Compatibility with complex component designs

- Stable performance for batch and mass production

By enabling precision welding, Normantherm supports Indian manufacturers in producing high-quality graphite–copper finished products.

Conclusion

Graphite and copper welding plays a vital role in producing high-performance components for electrical and thermal management applications. Vacuum welding ensures strong, reliable bonds and consistent material performance. With advanced vacuum furnace technology, Normantherm continues to support India’s industrial growth by enabling high-quality graphite–copper finished products.