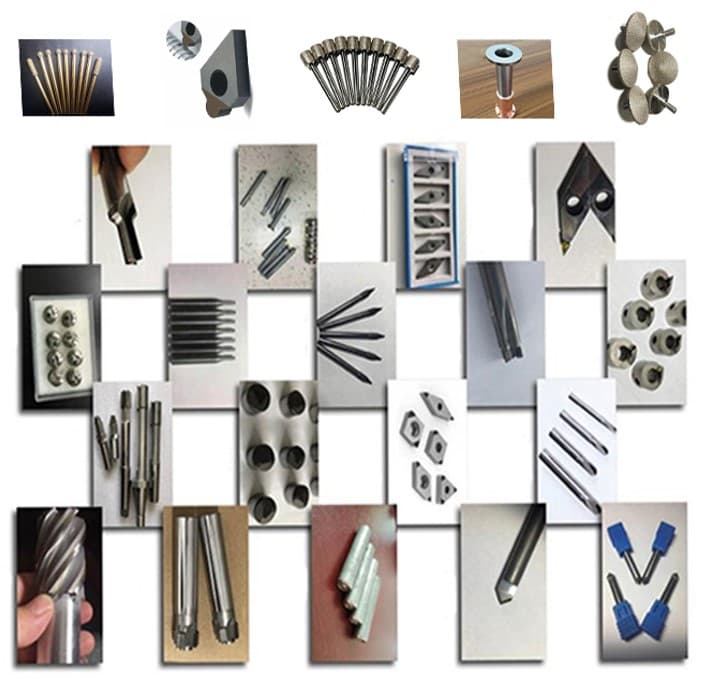

Tools and dies Industry

Vacuum brazing is widely applied in the tools and dies industry for manufacturing high-performance components such as cutting tools, grinding wheels, stamping dies, extrusion dies, and injection molds. It is especially valuable in the production of diamond tools, including diamond saw blades, grinding wheels, rollers, drill bits, engraving knives, beads, and grinding heads, used across woodworking, stone processing, glass cutting, and construction industries. These vacuum-brazed tools are crucial across sectors such as automotive, aerospace, electronics, metallurgy, geology, military, and infrastructure, where precision, strength, and durability are essential.

Articles

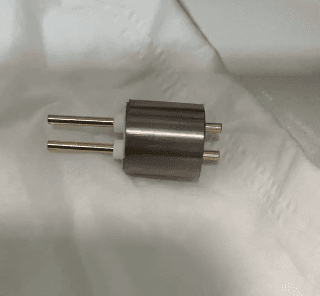

Stainless Steel and Gold-Plated Stainless Steel Pins with Ceramic Soldering

Stainless steel and gold-plated stainless steel pins joined through precision ceramic soldering are designed for applications that demand dependable electrical connectivity and long-term structural stability.

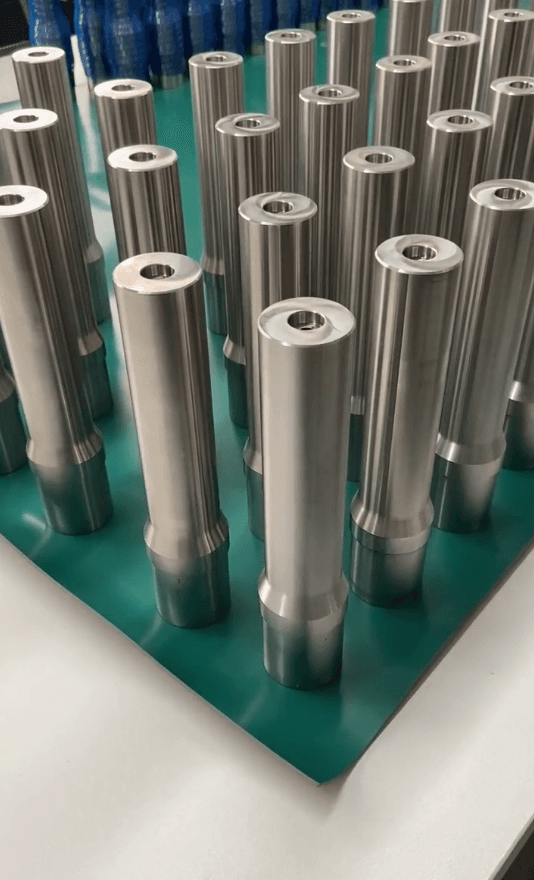

Vacuum Brazing of PDC to Stainless Steel Shafts for High-Performance Tools & Dies

Vacuum brazing of PDC to stainless steel shafts for tools and dies ensures strong, oxidation-free joints. Learn how Normantherm vacuum furnaces deliver precise temperature control and high-quality brazing for advanced tooling applications.

Vacuum Brazing PDC to Stainless Steel

Polycrystalline diamond compact (PDC) components are widely used in cutting, drilling, and wear-resistant applications due to their exceptional hardness and durability.

Vacuum Brazing PDC to Stainless Steel

Polycrystalline diamond compact (PDC) components are widely used in cutting, drilling, and wear-resistant applications due to their exceptional hardness and durability.

Stainless Steel and Gold-Plated Stainless Steel Pins with Ceramic Soldering

Stainless steel and gold-plated stainless steel pins joined by ceramic soldering are used in applications that demand high reliability stable electrical performance and long service life.