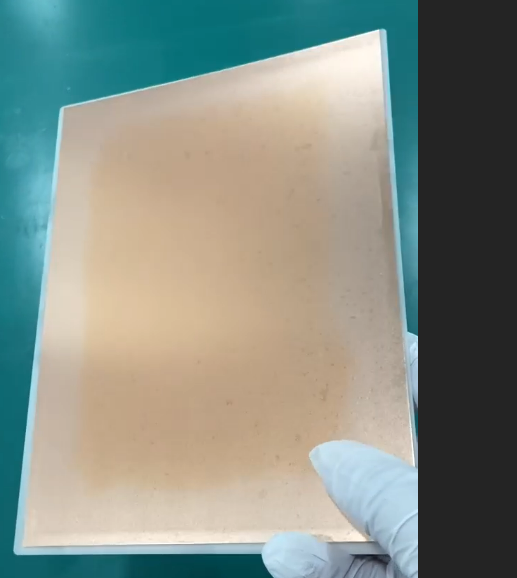

AMB Ceramic Copper-Clad Laminate Vacuum Brazing Finished Products for Power Electronics

AMB ceramic copper-clad laminates are widely used as high-performance substrates in power electronics due to their excellent thermal conductivity, electrical insulation, and mechanical strength. The finished product plays a vital role in applications such as IGBT modules, EV inverters, power control units, and renewable energy systems.

As India continues to expand its power electronics and electric mobility ecosystem, the quality and reliability of AMB substrates have become increasingly important.

Importance of the Finished AMB Product

The finished AMB ceramic copper-clad laminate must meet strict performance and dimensional requirements. Any defects at the copper-ceramic interface can lead to thermal resistance, electrical failure, or reduced service life.

A high-quality finished product offers:

- Strong metallurgical bonding between copper and ceramic

- Excellent thermal dissipation for high-power devices

- High dielectric strength and insulation reliability

- Flat, uniform surfaces suitable for module assembly

- Long-term stability under thermal cycling

These characteristics make AMB substrates ideal for demanding power electronic environments.

Role of Vacuum Brazing in Achieving Final Quality

Vacuum brazing is the defining process that determines the quality of the finished AMB laminate. In a high-vacuum environment:

- Oxidation of copper is completely eliminated

- Active metal alloys react uniformly with ceramic

- Void-free, continuous bonding layers are formed

- Thermal and mechanical properties remain consistent

- Post-processing and surface cleaning are minimized

This controlled process ensures that the finished product meets both electrical and mechanical performance standards.

Relevance to India’s Power Electronics and EV Industry

India’s rapid growth in EV manufacturing, renewable energy integration, and industrial power systems has increased demand for reliable, high-efficiency substrates. Finished AMB ceramic copper-clad laminates are critical components in:

- EV traction inverters

- IGBT and power semiconductor modules

- Solar and wind power converters

- Industrial motor drives and power supplies

Manufacturers require substrates that comply with global quality benchmarks while supporting scalable production.

Normantherm’s Role in AMB Finished Product Quality

Normantherm provides advanced vacuum brazing furnaces specifically engineered for AMB ceramic copper-clad laminate production. Our systems deliver:

- High-vacuum, oxygen-free brazing environments

- Uniform temperature distribution across substrates

- Stable activation of active metal brazing alloys

- Consistent bonding quality for batch and mass production

- Proven reliability for power electronics applications

By enabling precise control throughout the brazing process, Normantherm ensures that manufacturers achieve high-quality finished AMB products ready for demanding industrial use.

Conclusion

The performance of AMB ceramic copper-clad laminates depends on the quality of the finished product achieved through precision vacuum brazing. With advanced furnace technology and process stability, Normantherm supports India’s growing power electronics and EV industries by delivering reliable, high-performance AMB substrates that meet international standards.