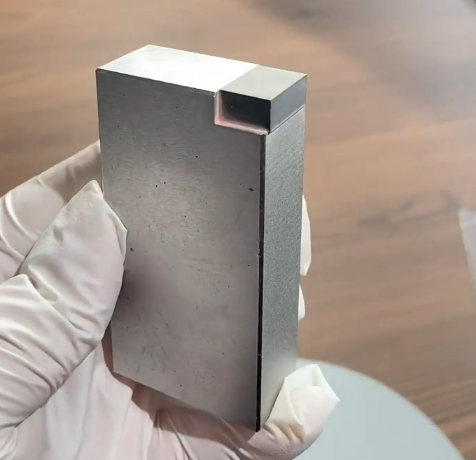

Finished Products Welded from Tungsten Steel and Mold Steel for High-Performance Tooling

Tooling and mold components operate under severe mechanical stress, abrasion, and thermal cycling. To achieve long service life and consistent performance, manufacturers often combine tungsten steel with mold steel in critical areas of finished products.

Vacuum brazing provides a reliable joining method for producing high-quality finished components from these dissimilar materials.

Material Advantages of Tungsten Steel and Mold Steel

Tungsten steel is valued for its extreme hardness and wear resistance, making it ideal for cutting and contact surfaces. Mold steel, on the other hand, offers excellent toughness, machinability, and dimensional stability.

By welding these materials together, manufacturers achieve a balance of durability and structural strength that cannot be obtained using a single material.

Why Vacuum Brazing Is Essential for Dissimilar-Material Joining

Traditional welding methods often struggle with the differences in thermal expansion and hardness between tungsten steel and mold steel. Vacuum brazing overcomes these challenges by providing controlled heating in an oxygen-free environment.

Key benefits include:

- Clean, oxidation-free joints

- Strong and uniform metallurgical bonding

- Reduced residual stress and distortion

- Excellent repeatability and dimensional control

These advantages are essential for precision tooling.

Performance Characteristics of Finished Products

Vacuum brazed finished products made from tungsten steel and mold steel exhibit:

- High wear resistance at functional surfaces

- Strong load-bearing capability

- Stable performance under repeated thermal cycles

- Improved service life and reliability

- Consistent quality in batch production

Such characteristics are critical for demanding industrial applications.

Applications in Tooling and Mold Industry

Finished products welded from tungsten steel and mold steel are widely used in:

- Injection molding tools

- Die-casting molds

- Stamping and forming dies

- Wear-resistant inserts and tooling components

As tooling complexity increases, vacuum brazing becomes a key enabling technology.

Normantherm’s Role in Tooling and Mold Vacuum Brazing

Normantherm designs and manufactures advanced vacuum brazing furnaces optimized for tooling and mold applications. Our systems provide:

- High-vacuum, contamination-free processing

- Precise temperature control and uniform heating

- Stable and repeatable brazing cycles

- Support for complex mold geometries

These capabilities help manufacturers achieve reliable and high-performance finished products.

Conclusion

Finished products welded from tungsten steel and mold steel using vacuum brazing deliver superior wear resistance, structural integrity, and long-term reliability. With advanced furnace technology and proven process control, Normantherm supports India’s tooling and mold-making industries by enabling dependable dissimilar-material joining solutions.