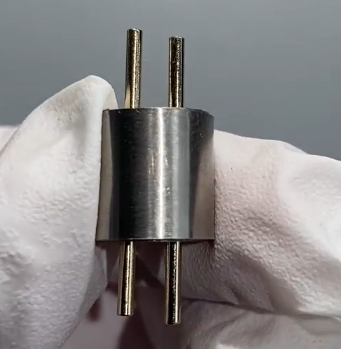

Ceramic Soldering of Stainless Steel and Gold-Plated Stainless Steel Pins for High-Reliability Components

Metal-to-ceramic assemblies are critical in industries where electrical insulation, corrosion resistance, and long-term reliability are essential. Stainless steel and gold-plated stainless steel pins combined with ceramic materials are widely used in electronic feedthroughs, sensors, and precision electrical components.

Vacuum brazing provides a controlled and reliable solution for producing these complex assemblies.

Challenges in Joining Metal Pins with Ceramic Materials

Ceramics and metals differ significantly in thermal expansion, melting behavior, and surface chemistry. Conventional soldering or brazing methods can result in poor wetting, weak joints, or cracking at the ceramic interface.

Key challenges include:

- Oxidation of metal surfaces

- Thermal stress at the metal-ceramic interface

- Inconsistent joint strength

- Contamination affecting electrical performance

These challenges demand a precise joining environment.

Advantages of Vacuum Brazing for Ceramic Soldering

Vacuum brazing enables clean, oxidation-free joining between stainless steel pins, gold-plated pins, and ceramic components. Controlled heating ensures proper wetting and strong metallurgical bonding without damaging sensitive materials.

Major advantages include:

- Hermetic and high-strength metal-ceramic joints

- Excellent electrical insulation and conductivity control

- Clean surfaces without flux residue

- Minimal thermal stress and distortion

- High repeatability for precision components

These benefits are essential for high-reliability applications.

Performance Characteristics of Finished Pin Assemblies

Vacuum-brazed stainless steel and gold-plated stainless steel pin assemblies offer:

- Stable electrical conductivity and insulation

- Excellent corrosion and oxidation resistance

- High mechanical strength and sealing integrity

- Long service life under thermal cycling

- Consistent quality in batch production

Such performance is critical in advanced electronic systems.

Applications in India’s Electronics and Electrical Industries

In India, ceramic-soldered stainless steel pin assemblies are commonly used in:

- Electrical feedthroughs and connectors

- Sensors and measurement devices

- Power electronics and control systems

- Medical and industrial electronic equipment

As reliability standards increase, vacuum brazing becomes a preferred manufacturing method.

Normantherm’s Role in Metal-Ceramic Vacuum Brazing

Normantherm designs and manufactures advanced vacuum brazing furnaces optimized for metal-to-ceramic joining. Our systems provide:

- High-vacuum, contamination-free processing

- Precise temperature control and uniform heating

- Stable and repeatable brazing cycles

- Support for complex ceramic-metal geometries

These capabilities enable manufacturers to produce high-quality, high-reliability components.

Conclusion

Stainless steel and gold-plated stainless steel pins with ceramic soldering produced through vacuum brazing deliver reliable electrical performance, strong sealing, and long-term stability. With advanced furnace technology and proven process control, Normantherm supports India’s electronics and electrical component industries by enabling dependable metal-ceramic joining solutions.