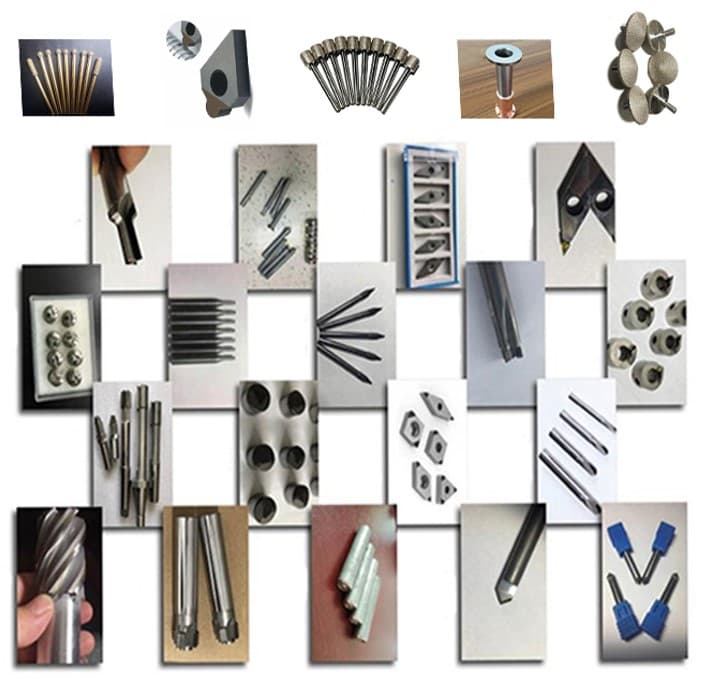

Tools and dies Industry

Vacuum brazing is widely applied in the tools and dies industry for manufacturing high-performance components such as cutting tools, grinding wheels, stamping dies, extrusion dies, and injection molds. It is especially valuable in the production of diamond tools, including diamond saw blades, grinding wheels, rollers, drill bits, engraving knives, beads, and grinding heads, used across woodworking, stone processing, glass cutting, and construction industries. These vacuum-brazed tools are crucial across sectors such as automotive, aerospace, electronics, metallurgy, geology, military, and infrastructure, where precision, strength, and durability are essential.

Articles

Vacuum Brazing of Silicon Nitride–Tungsten Electrode Silver Contact

Vacuum brazing is a reliable and precise joining method for manufacturing silicon nitride–tungsten electrode silver contacts, which are widely used in high-performance electrical, electronic, and power-control applications.

Vacuum Brazing of Tungsten Steel Saw Blades: Process, Advantages & Industrial Applications

Vacuum brazing of tungsten steel saw blades ensures clean joints, high wear resistance, and long tool life. Learn the process, benefits, and industrial applications with Normantherm’s 15+ years of expertise.

Vacuum Brazing of Tungsten Steel Saw Blades – Finished Product

Vacuum brazing is a key manufacturing process used to produce high-performance tungsten steel saw blades, where tungsten carbide tips are securely bonded to a steel blade body.

Vacuum Brazed Wear-Resistant Steel Saw Blade

In high performance cutting, the weak point is often the joint, not the steel. Wear-resistant steel saw blades demand a joint that can withstand high cutting loads, thermal cycling, and severe abrasion without premature failure.

Welded Tungsten Steel Saw Blades for Industrial Cutting Applications

Tungsten steel saw blades play a critical role in industrial cutting operations where durability, precision, and long service life are required.