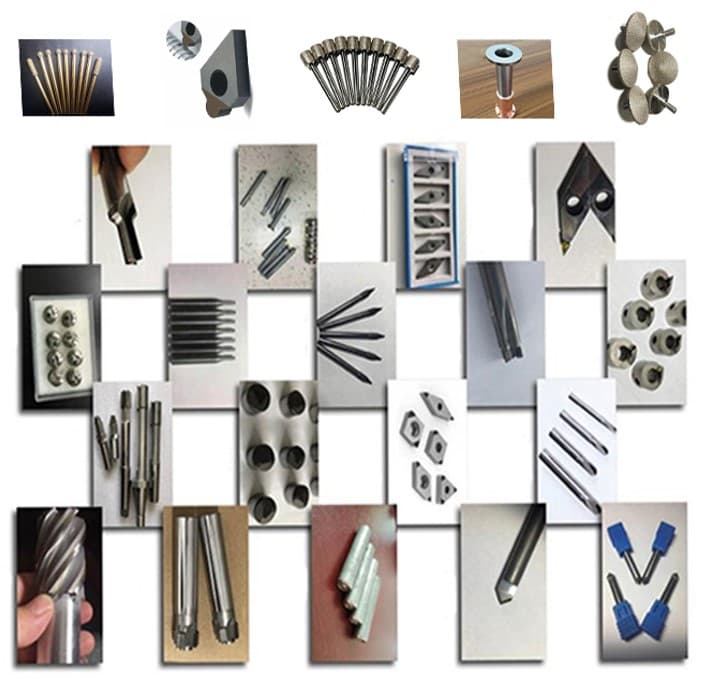

Tools and dies Industry

Vacuum brazing is widely applied in the tools and dies industry for manufacturing high-performance components such as cutting tools, grinding wheels, stamping dies, extrusion dies, and injection molds. It is especially valuable in the production of diamond tools, including diamond saw blades, grinding wheels, rollers, drill bits, engraving knives, beads, and grinding heads, used across woodworking, stone processing, glass cutting, and construction industries. These vacuum-brazed tools are crucial across sectors such as automotive, aerospace, electronics, metallurgy, geology, military, and infrastructure, where precision, strength, and durability are essential.

Articles

Vacuum Brazing of PDC and Stainless Steel – Finished Product

Vacuum brazing is a critical manufacturing process used to produce high-performance PDC (Polycrystalline Diamond Compact) and stainless steel finished products, especially for cutting, drilling, and wear-resistant applications.

Welding of Tungsten Steel with No. 45 Steel Finished Products

Welding of tungsten steel with No. 45 steel is a specialized manufacturing process used to produce high-strength finished products for demanding industrial applications.

Welding of 304 Stainless Steel and Oxygen-Free Copper for High-Performance Applications

Welding of 304 stainless steel with oxygen-free copper is a specialized joining process used in applications that demand reliable mechanical strength and efficient thermal performance.

Vacuum Brazing of Tungsten Steel and Mold Steel

Vacuum brazing is a proven and efficient joining process for bonding tungsten steel with mold steel, especially in tooling and mold manufacturing where high wear resistance and structural strength are required.

Vacuum Brazed Tungsten Steel and Mold Steel for the Tooling Industry

Discover how vacuum brazed tungsten steel and mold steel enhance tooling performance in India. Learn about material properties, brazing process with nickel/silver paste, and Normantherm’s 15+ years of vacuum furnace expertise for high-precision tooling.