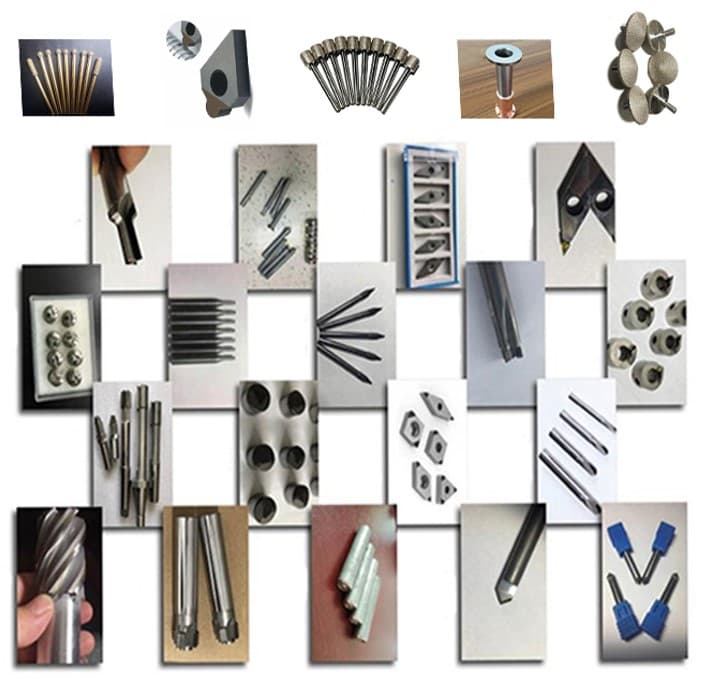

Tools and dies Industry

Vacuum brazing is widely applied in the tools and dies industry for manufacturing high-performance components such as cutting tools, grinding wheels, stamping dies, extrusion dies, and injection molds. It is especially valuable in the production of diamond tools, including diamond saw blades, grinding wheels, rollers, drill bits, engraving knives, beads, and grinding heads, used across woodworking, stone processing, glass cutting, and construction industries. These vacuum-brazed tools are crucial across sectors such as automotive, aerospace, electronics, metallurgy, geology, military, and infrastructure, where precision, strength, and durability are essential.

Articles

Vacuum Brazing of CR12MoV Tool Steel with Tungsten Carbide

Vacuum brazing is an advanced and reliable joining technique used to bond CR12MoV tool steel with tungsten carbide, especially for high-wear tooling such as cutting tools, dies, punches, and industrial blades.

Vacuum Brazing of CR12MoV Tool Steel with Tungsten Carbide

Tooling and die components operating under severe wear and impact conditions require materials that combine toughness with extreme hardness. Vacuum brazing CR12MoV tool steel with tungsten carbide provides an effective solution for manufacturing high-performance tools.

Finished Cemented Carbide Ultrasonic Cutting Tools Using Vacuum Brazing

Vacuum brazing cemented carbide YG10 with titanium alloy has become a reliable solution for manufacturing high-performance ultrasonic cutting tools.

Vacuum Brazed Tools and Dies for High-Precision Manufacturing

The tooling and die-making industry demands components with exceptional strength, wear resistance, and dimensional accuracy.

Vacuum Brazing of Tungsten Steel Saw Blades for High-Precision Cutting

Vacuum brazing is a critical manufacturing process for producing high-performance tungsten steel saw blades where tungsten carbide tips are permanently bonded to a steel blade body.