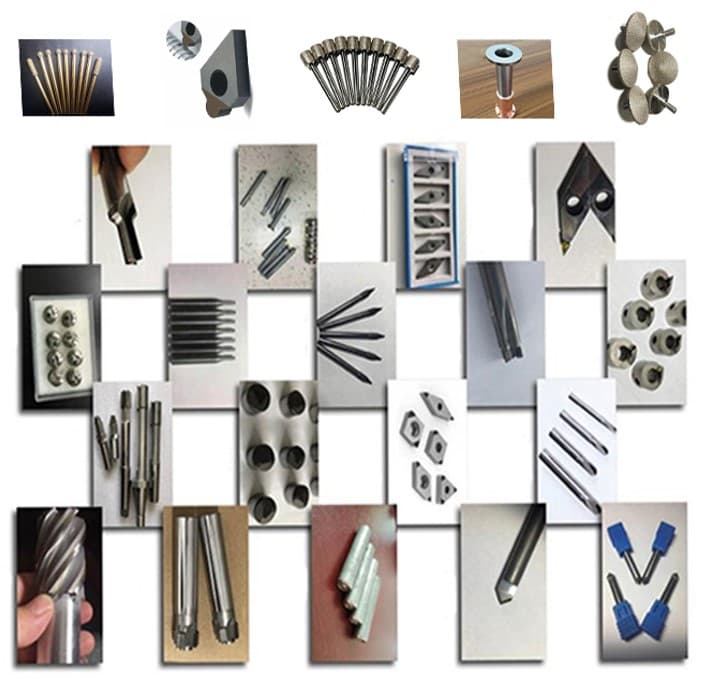

Tools and dies Industry

Vacuum brazing is widely applied in the tools and dies industry for manufacturing high-performance components such as cutting tools, grinding wheels, stamping dies, extrusion dies, and injection molds. It is especially valuable in the production of diamond tools, including diamond saw blades, grinding wheels, rollers, drill bits, engraving knives, beads, and grinding heads, used across woodworking, stone processing, glass cutting, and construction industries. These vacuum-brazed tools are crucial across sectors such as automotive, aerospace, electronics, metallurgy, geology, military, and infrastructure, where precision, strength, and durability are essential.

Articles

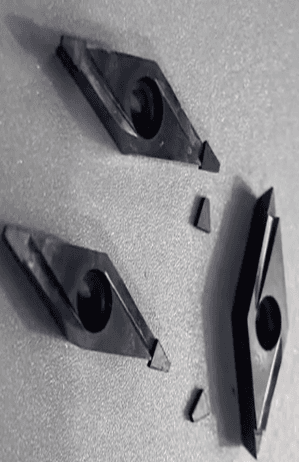

Vacuum Brazing of CBN Tools

Vacuum brazing is a highly advanced joining process used in the manufacture of CBN (Cubic Boron Nitride) cutting tools, which are designed for machining hardened steels and high-wear materials.

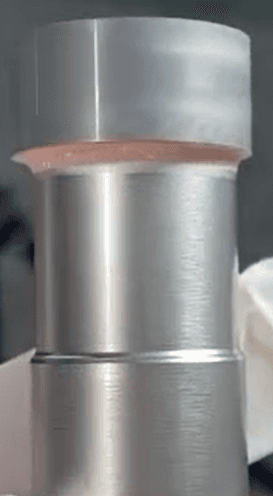

Vacuum Brazing of Mold Steel and Tungsten Steel

Vacuum brazing is an advanced and reliable joining method for bonding mold steel with tungsten steel, especially in tooling and mold-making applications where high strength and wear resistance are required.

Vacuum Brazed Finished Products Made of Mold Steel and Tungsten Steel

Tooling and mold components often operate under extreme wear, pressure, and repetitive loading. Combining mold steel with tungsten steel provides an effective balance of toughness and hardness required for long service life.

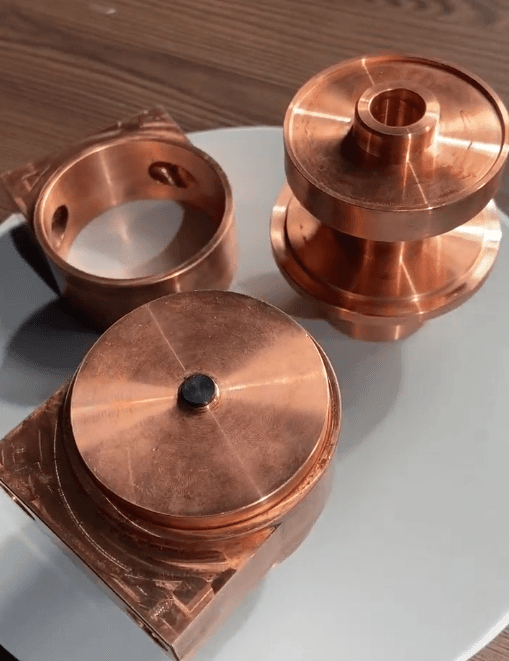

Reliable Joining Technology for Oxygen-Free Copper Materials

Oxygen-free copper is a high-purity copper material with extremely low oxygen content, usually less than 0.001%. Compared to regular electrolytic copper, oxygen-free copper offers higher electrical conductivity (above 101 % IACS), superior thermal conductivity (~390 W/m·K at 20 °C).

Vacuum Brazing of Molybdenum-Copper Alloy with Stainless Steel

Molybdenum copper alloy is a composite material that combines the properties of molybdenum and copper. It has high thermal conductivity, a low coefficient of thermal expansion, and good resistance to high temperatures.