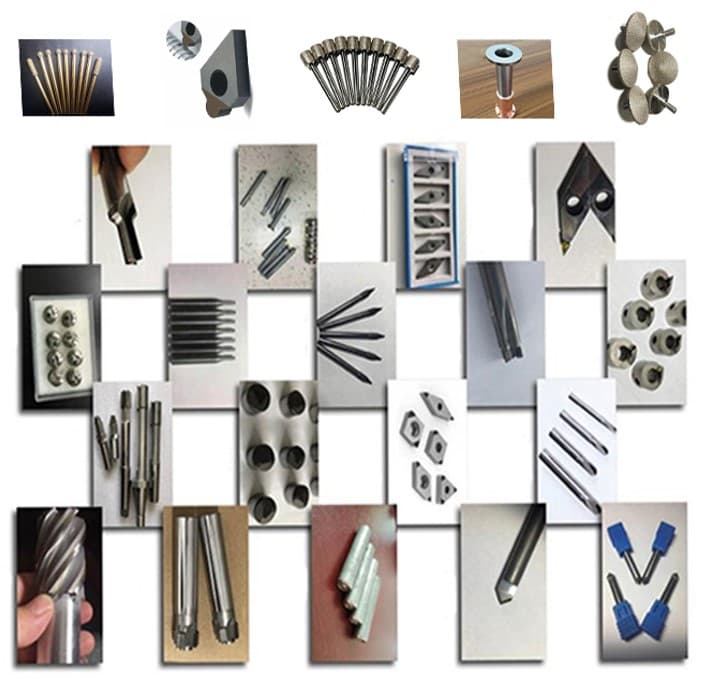

Tools and dies Industry

Vacuum brazing is widely applied in the tools and dies industry for manufacturing high-performance components such as cutting tools, grinding wheels, stamping dies, extrusion dies, and injection molds. It is especially valuable in the production of diamond tools, including diamond saw blades, grinding wheels, rollers, drill bits, engraving knives, beads, and grinding heads, used across woodworking, stone processing, glass cutting, and construction industries. These vacuum-brazed tools are crucial across sectors such as automotive, aerospace, electronics, metallurgy, geology, military, and infrastructure, where precision, strength, and durability are essential.

Articles

Tungsten Steel and No. 45 Steel Vacuum Brazing for Tools & Dies Industry

Tungsten steel to No. 45 steel vacuum brazing for tools and dies. Normantherm vacuum furnaces help Indian manufacturers achieve stronger joints, higher accuracy, and longer tool life.

Brazed Product of Tungsten Carbide and Tool Steel Using Vacuum Furnace Technology

Brazing tungsten carbide to tool steel is a critical manufacturing process used in high-performance industrial components where wear resistance, strength, and dimensional stability are essential.

Vacuum Brazing of Tungsten Steel with No. 45 Steel

Vacuum brazing is an efficient and reliable joining method for bonding tungsten steel with No. 45 steel (medium-carbon steel), widely used in cutting tools, wear parts, and heavy-duty mechanical components.

Vacuum Brazing of Tungsten Carbide to 45# Steel

Tungsten carbide and 45# carbon steel are widely used together in tooling and wear-resistant components, combining extreme hardness with good structural toughness.

Oxygen-Free Copper Welded Finished Products for High-Performance Applications

Oxygen-free copper welded finished products are widely used in industries where superior electrical conductivity and efficient thermal management are critical. Oxygen-free copper is manufactured with extremely low oxygen content which allows it to be welded without internal oxidation porosity.