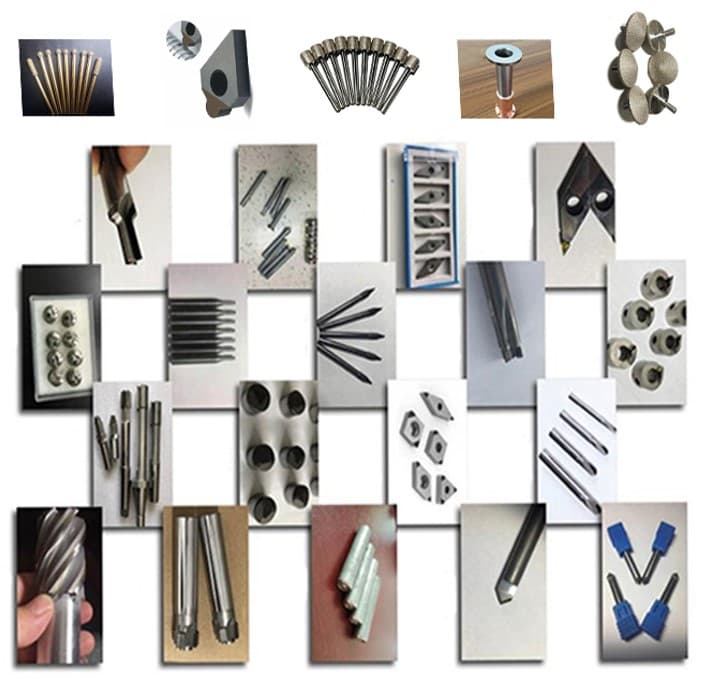

Tools and dies Industry

Vacuum brazing is widely applied in the tools and dies industry for manufacturing high-performance components such as cutting tools, grinding wheels, stamping dies, extrusion dies, and injection molds. It is especially valuable in the production of diamond tools, including diamond saw blades, grinding wheels, rollers, drill bits, engraving knives, beads, and grinding heads, used across woodworking, stone processing, glass cutting, and construction industries. These vacuum-brazed tools are crucial across sectors such as automotive, aerospace, electronics, metallurgy, geology, military, and infrastructure, where precision, strength, and durability are essential.

Articles

Vacuum Brazing of Cemented Carbide Ultrasonic Cutting Tools (YG10) with Titanium Alloy

Vacuum brazing is a highly reliable joining process for manufacturing cemented carbide ultrasonic cutting tools made from YG10 grade bonded to titanium alloy holders.

Welding of Tungsten Steel and Stainless Steel

Welding tungsten steel and stainless steel is a challenging process due to the large differences in hardness melting temperature and thermal expansion between the two materials.

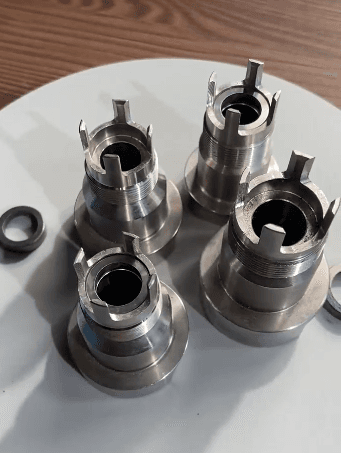

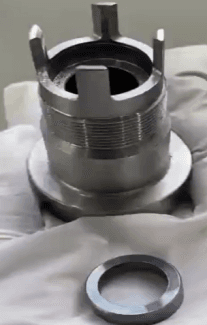

Vacuum Brazing of Tungsten Steel with Stainless Steel

Vacuum brazing is an effective and precise method for joining tungsten steel with stainless steel, especially in applications requiring high wear resistance combined with corrosion resistance.

Vacuum Brazing of Tungsten Steel and Stainless Steel for Tools and Dies Industry

Vacuum brazing of tungsten steel & stainless steel for tools & dies in India. Normantherm furnaces ensure precision, strength, and defect-free joints.

CR12MoV Steel and Tungsten Carbide Vacuum Brazing: Precision Solutions for Tools and Dies Industry

Discover precision vacuum brazing of CR12MoV steel and tungsten carbide for tools & dies in India. Learn about vacuum brazing advantages, filler materials, and Normantherm furnaces for high-strength, contamination-free joints.