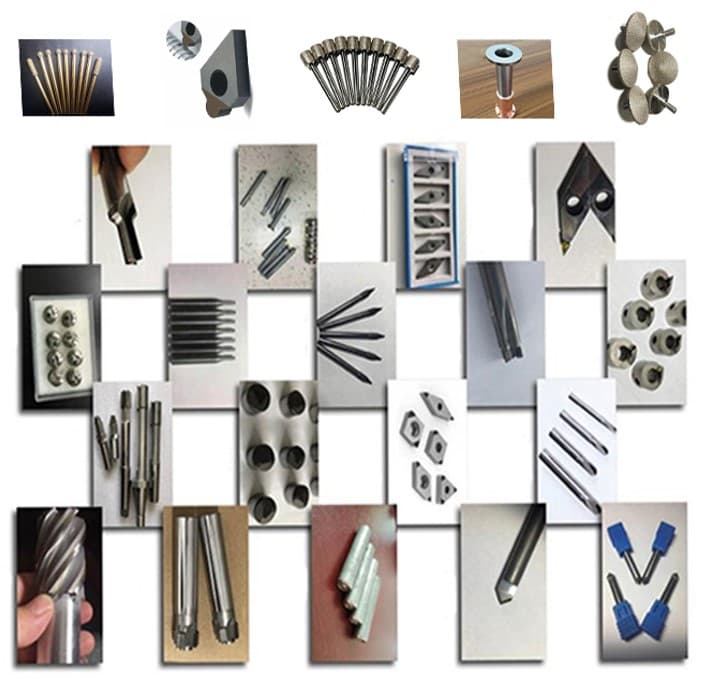

Tools and dies Industry

Vacuum brazing is widely applied in the tools and dies industry for manufacturing high-performance components such as cutting tools, grinding wheels, stamping dies, extrusion dies, and injection molds. It is especially valuable in the production of diamond tools, including diamond saw blades, grinding wheels, rollers, drill bits, engraving knives, beads, and grinding heads, used across woodworking, stone processing, glass cutting, and construction industries. These vacuum-brazed tools are crucial across sectors such as automotive, aerospace, electronics, metallurgy, geology, military, and infrastructure, where precision, strength, and durability are essential.

Articles

Vacuum Brazing of 304 Stainless Steel and Oxygen-Free Copper

Vacuum brazing is an effective and reliable joining process for bonding 304 stainless steel with oxygen-free copper, especially in applications requiring high thermal efficiency, corrosion resistance, and leak-tight performance.

Vacuum Brazing of Diamond Tools

This article discusses vacuum brazing of diamond materials used in grinding wheels, rollers, saw blades, grinding heads, and similar products. Compared with traditional electroplating and sintering methods, vacuum brazing offers clear advantages, including higher efficiency and stronger bonding.

Vacuum Heat Treatment of Nickel-Titanium Materials

Common products made from these materials include root canal files, vascular stents, pulp extraction needles, and delivery needles, which are widely used in medical fields such as human implants, bone support technologies, dentistry, etc.

Oxygen-Free Copper Vacuum Brazing

Oxygen-free copper vacuum brazing is a precision joining process used in applications where high conductivity, cleanliness, and joint reliability are essential.

Vacuum Brazing of Mold Steel and Tungsten Steel for High-Performance Tooling

Mold and die components are subjected to extreme mechanical loads, abrasion, and thermal cycling. To achieve long service life and consistent performance, manufacturers often combine mold steel with tungsten steel in critical wear zones.