Automobiles Industry

Vacuum brazing is essential in the manufacturing of a wide range of automobile components that demand strong, precise, and contamination-free joints. It is commonly used in parts such as oil coolers, heat exchangers, radiators, fuel system components, transmission parts, and EGR (Exhaust Gas Recirculation) coolers. Additionally, vacuum brazing is critical for joining aluminum cold plates, liquid cooling heat sink plates, carbide tipped gear hobs, laminated aluminum evaporators, high voltage DC relays, battery coolers, and aluminum alloy chassis.

Articles

Vacuum Brazing of Silicon Nitride-Tungsten Electrodes with Silver Contact

With Normantherm Vacuum Furnaces, manufacturers gain not just a heat treatment and brazing system, but a process solution that enhances product quality, reduces rework, and supports advanced material innovation.

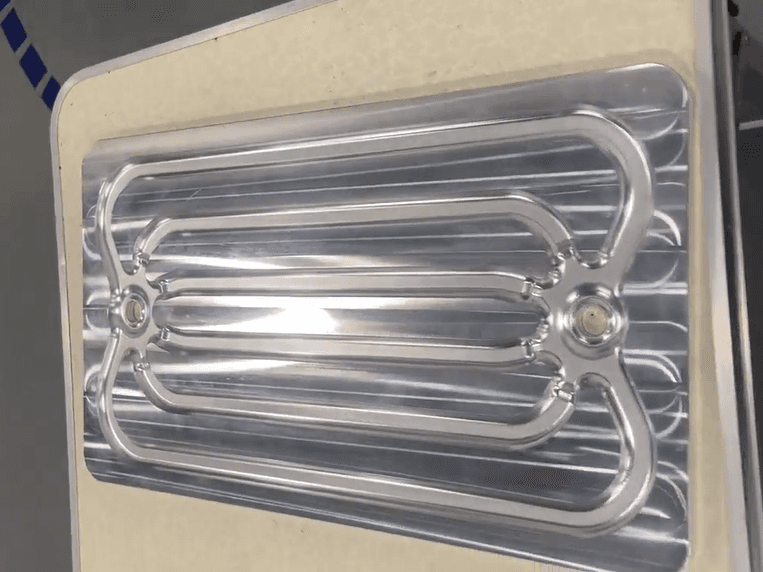

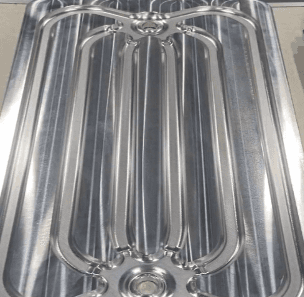

Vacuum Brazing of 6061 Aluminum Alloy Water-Cooled Plates for EV Thermal Management

Discover how Indian manufacturers use vacuum brazing for 6061 aluminum alloy water-cooled plates in EV thermal management. Normantherm vacuum furnaces ensure strong, high-thermal-conductivity joints, precise temperature control, and reliable, defect-free performance for India’s growing EV industry.

Vacuum Brazing of Titanium Alloy Finished Products

Vacuum brazing of titanium alloy is an advanced joining technology used to manufacture high-performance finished products that demand exceptional strength dimensional accuracy and long-term reliability.

Heat Treatment of Nickel-Plated Alloy Springs

Heat treatment is a critical manufacturing step that directly determines the strength elasticity fatigue life and long-term reliability of nickel-plated alloy springs.

Vacuum Brazing of 6061 Aluminum Alloy Water-Cooled Plates

6061 aluminum provides excellent thermal conductivity strong mechanical properties corrosion resistance and easy machinability making it ideal for precision cooling plates with internal flow channels.