Automobiles Industry

Vacuum brazing is essential in the manufacturing of a wide range of automobile components that demand strong, precise, and contamination-free joints. It is commonly used in parts such as oil coolers, heat exchangers, radiators, fuel system components, transmission parts, and EGR (Exhaust Gas Recirculation) coolers. Additionally, vacuum brazing is critical for joining aluminum cold plates, liquid cooling heat sink plates, carbide tipped gear hobs, laminated aluminum evaporators, high voltage DC relays, battery coolers, and aluminum alloy chassis.

Articles

Vacuum Brazing Tungsten Steel to Tool Steel

Brazing tungsten-based materials to tool steel is a demanding process that requires precise control of materials, atmosphere, and thermal parameters.

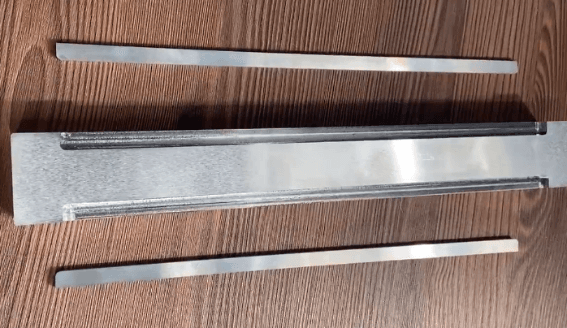

Finished Products Made of Mold Steel and Tungsten Steel

Finished products made from mold steel and tungsten steel are designed for high-load and high-wear industrial environments where strength and precision matter most.

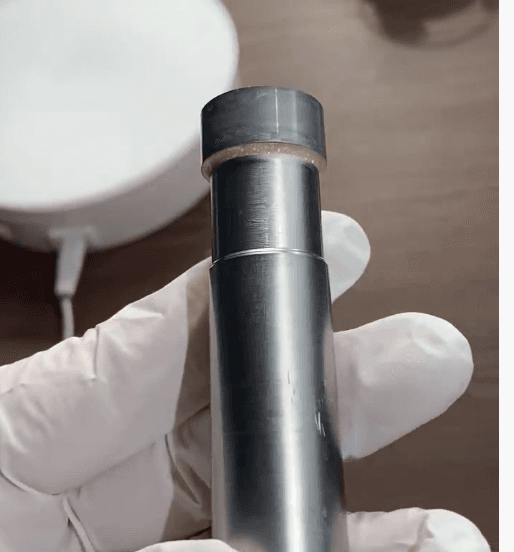

Vacuum Brazed Assembly of Die Steel and Tungsten Steel

The vacuum brazed assembly of die steel and tungsten steel is commonly used in tooling applications where both strength and wear resistance are required in the same component.

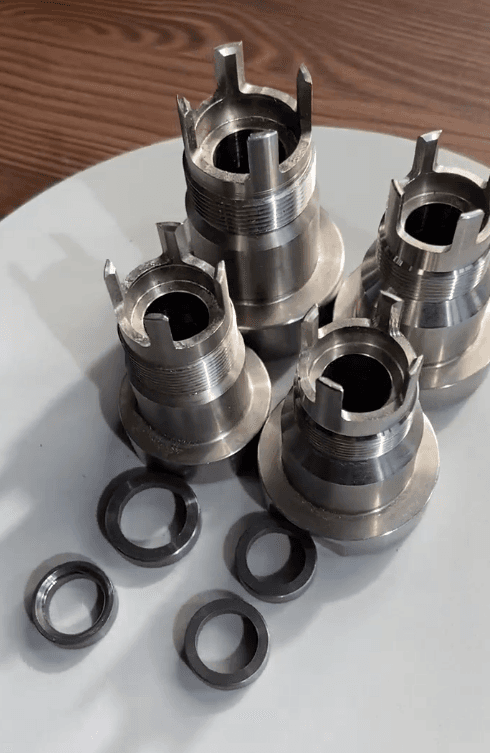

Welding Tungsten Carbide to Stainless Steel in Vacuum Furnaces

Joining tungsten carbide to stainless steel is a critical requirement in many industrial applications where extreme wear resistance must be combined with structural strength and corrosion resistance.

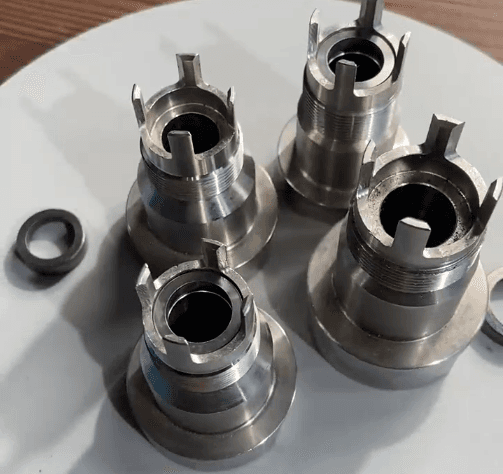

Vacuum Brazing of Tungsten Steel and Stainless Steel

Modern industrial components often require the combination of materials with very different properties. Tungsten steel offers exceptional hardness and wear resistance, while stainless steel provides corrosion resistance and structural toughness.