Aerospace Industry

Vacuum brazing is a vital process in the aerospace industry, where precision, strength, and reliability are non-negotiable. It is extensively used in the production of turbine blades, heat exchangers, fuel system components, jet engine parts, and structural assemblies that must withstand extreme temperatures and mechanical stress. The process enables the joining of dissimilar metals and intricate assemblies without the use of flux, eliminating the risk of contamination and ensuring the highest levels of cleanliness. This is crucial in aerospace applications, where even microscopic impurities can compromise performance or safety.

Articles

Precision Joining of TC4 Titanium and 4J29 Kovar for Aerospace Applications

In aerospace systems, the integration of dissimilar materials is often required to achieve optimal mechanical strength, thermal stability and hermetic sealing.

Vacuum Brazed Copper Water-Cooled Plates

Vacuum brazed copper water-cooled plates are advanced thermal management components used in high-heat industrial and scientific applications such as induction heating systems, power electronics, furnaces, and aerospace equipment.

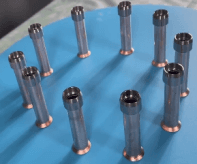

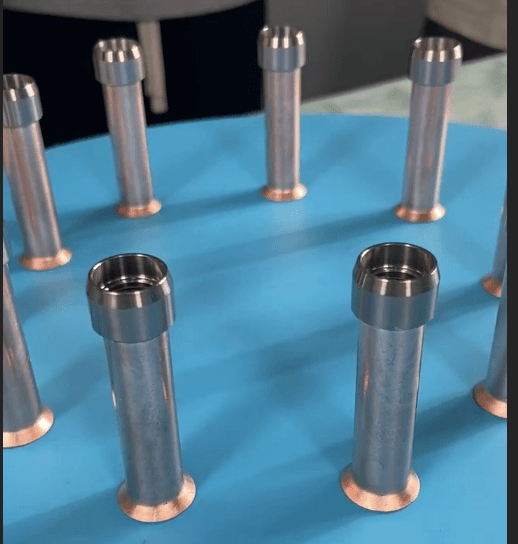

Vacuum Brazing of Stainless Steel Sleeve for Aerospace Applications in India

Explore how Normantherm’s vacuum brazing furnaces deliver high-quality stainless steel sleeves for aerospace applications like actuators, landing gear, and hydraulic assemblies in India.

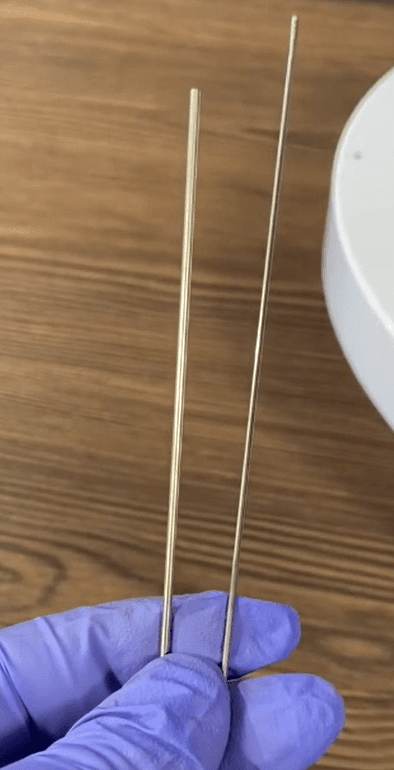

Vacuum Brazing of Titanium Alloy and Copper

Vacuum brazing of titanium alloy and copper is a highly specialized joining technique used to achieve strong, clean, and thermally efficient bonds between these two dissimilar metals. Titanium alloys offer excellent strength-to-weight ratio and corrosion resistance.

Titanium-Copper Vacuum Brazing — Enabling Lightweight Thermal Management in Aerospace Engineering

In aerospace systems, weight reduction and thermal efficiency are critical. Titanium alloys offer exceptional strength-to-weight ratio, while copper provides superior heat conduction.