Medical Industry

Vacuum brazing plays a crucial role in the manufacturing of various high-precision medical components. It is widely used in the production of surgical instruments, dental tools, orthopedic implants, and electronic medical devices such as pacemakers and defibrillators. The process allows for the joining of dissimilar metals and complex geometries without introducing impurities, making it ideal for components that require high structural integrity and cleanliness. It ensures strong, leak-tight joints in medical assemblies, which is essential for patient safety and device performance.

Articles

Vacuum Demagnetization of 316 Stainless Steel for the Medical Device Industry

316 stainless steel is widely used in the medical device and surgical instrument industry because of its corrosion resistance, biocompatibility, and mechanical strength.

Vacuum Annealing of 304 Stainless Steel Eyeglass Frames for the Eyewear Manufacturing Industry

Normantherm provides advanced vacuum furnace systems designed for precise annealing of stainless steels, including 304 stainless steel used in metal eyeglass frames.

Vacuum Annealing of 304 Stainless Steel Eyeglass Frames for Precision Manufacturing in India

Discover how vacuum annealing enhances the quality of 304 stainless steel eyeglass frames. Learn its benefits for India’s eyewear manufacturing industry and explore advanced vacuum furnace solutions from Normantherm for superior surface finish and precision results.

Nickel-Titanium (NiTi) Occluders Heat Treatment for the Indian Medical Device Industry

Discover how Nickel-Titanium (NiTi) occluders are heat-treated for optimal performance in cardiac devices. Learn about the importance of precise thermal processing and how Normantherm’s vacuum furnaces support safe, reliable, and high-quality occluder manufacturing in India.

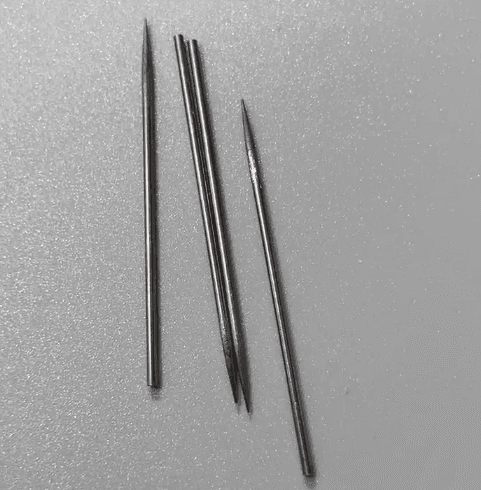

Vacuum Brazing and Heat Treatment of 420 Stainless Steel Suture Needles

In the medical industry, tools like suture needles require an exceptional combination of sharpness, strength, and corrosion resistance. 420 stainless steel, known for its high carbon content and martensitic structure, is widely used in surgical instruments.