YG10 and Titanium Alloy Welding for Ultrasonic Applications

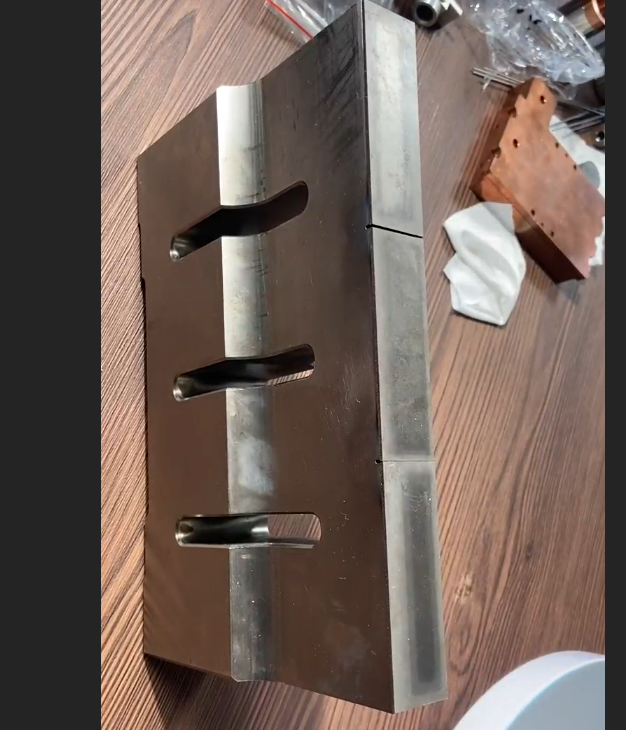

Ultrasonic equipment relies on components that operate under extreme vibration, cyclic stress, and localized heat generation. Materials used in ultrasonic horns, sonotrodes, and tooling must deliver a precise balance of hardness, wear resistance, and fatigue strength. For this reason, the combination of YG10 cemented carbide and titanium alloy has become increasingly important in high-performance ultrasonic applications.

As India’s electronics, packaging, plastics, and precision manufacturing industries expand, demand for durable ultrasonic tooling continues to rise.

Why YG10 Carbide and Titanium Alloy Are Used Together

YG10 cemented carbide offers high hardness, excellent wear resistance, and long service life in contact-intensive applications. Titanium alloy, on the other hand, provides low density, high strength, and outstanding fatigue resistance under vibration.

When joined correctly, this material combination offers:

- Superior wear resistance at contact surfaces

- High vibration endurance for ultrasonic frequencies

- Reduced tool wear and longer operational life

- Stable amplitude transmission in ultrasonic systems

- Improved reliability under cyclic loading

This makes YG10–titanium assemblies ideal for ultrasonic cutting, welding, and machining equipment.

Challenges in Welding Carbide to Titanium

Welding cemented carbide to titanium alloy presents significant metallurgical challenges due to differences in thermal expansion, melting behavior, and chemical reactivity. Conventional joining methods often lead to:

- Cracking at the joint interface

- Weak bonding due to oxidation

- Residual stresses from uneven cooling

- Reduced fatigue life under ultrasonic vibration

To overcome these challenges, a controlled vacuum welding environment is essential.

Role of Vacuum Welding in Ultrasonic Components

Vacuum welding eliminates oxygen and contaminants during the joining process, enabling clean interfacial reactions and strong metallurgical bonds. Controlled heating allows diffusion and bonding without damaging either material.

Key benefits include:

- Oxide-free joining surfaces

- Reduced residual stress

- Uniform joint strength

- Improved vibration and fatigue resistance

- Consistent quality for production-scale manufacturing

This ensures that welded components maintain performance stability during long-term ultrasonic operation.

Relevance to India’s Ultrasonic Manufacturing Sector

India’s ultrasonic equipment market is growing across industries such as electronics assembly, medical devices, packaging, automotive components, and plastic welding. Manufacturers require tooling that meets high durability and precision standards.

Vacuum-welded YG10 and titanium alloy components provide Indian manufacturers with reliable solutions for high-frequency applications, enabling compliance with international quality and performance benchmarks.

Normantherm’s Expertise in Vacuum Welding

Normantherm designs and manufactures advanced vacuum welding furnaces optimized for dissimilar material joining, including carbide-to-titanium applications. Our systems offer:

- High-vacuum, oxygen-free welding environments

- Precise temperature and process control

- Stable joint formation for vibration-critical components

- Repeatable results for batch and mass production

- Proven performance in ultrasonic tooling applications

By delivering advanced vacuum welding solutions, Normantherm supports Indian ultrasonic equipment manufacturers in producing high-quality, long-lasting components.

Conclusion

YG10 cemented carbide and titanium alloy welding plays a crucial role in ultrasonic applications where wear resistance, vibration endurance, and joint reliability are essential. Through precision vacuum welding technology, Normantherm enables manufacturers to achieve strong, stable bonds that perform consistently under ultrasonic conditions, supporting the growth of India’s advanced ultrasonic manufacturing industry.