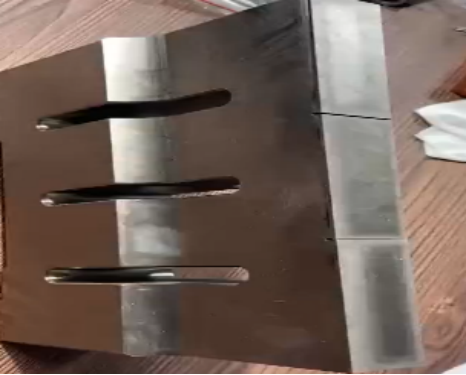

Vacuum Brazing of YG10 Carbide and Titanium Alloy for High-Strength Applications

Vacuum brazing of YG10 cemented carbide and titanium alloy is an advanced joining process used to produce strong, precise and reliable bonds between these two dissimilar materials. YG10 carbide is valued for its high hardness and excellent wear resistance, while titanium alloys are known for their high strength-to-weight ratio and corrosion resistance. Due to the brittleness of carbide and the high reactivity of titanium at elevated temperatures, conventional welding methods are not suitable. Vacuum brazing provides an oxygen-free environment that ensures clean interfaces and consistent joint quality.

Vacuum Brazing Process for YG10 Carbide Titanium Joints

In this process, a carefully selected active brazing filler metal is placed at the interface between the YG10 carbide and titanium alloy components. The assembled parts are heated uniformly in a high-vacuum furnace, preventing oxidation and contamination. As the brazing temperature is reached, the filler metal melts and wets both the carbide and titanium surfaces, forming a strong metallurgical bond.

Controlled heating and cooling cycles are critical to minimize thermal stress, reduce the risk of cracking, and maintain the dimensional accuracy of the components.

Advantages and Applications

Vacuum-brazed YG10 carbide titanium assemblies offer:

· high joint strength and wear resistance

· clean, oxidation-free bonding surfaces

· minimal thermal distortion

· excellent durability in demanding environments

These joints are widely used in cutting and drilling tools, aerospace components, wear-resistant parts, and high-performance industrial assemblies, where precision, reliability and long service life are essential.