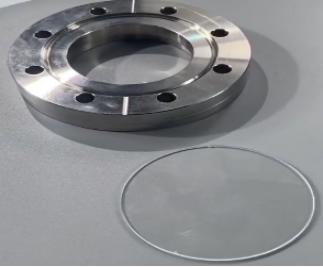

Vacuum Brazing of Titanium Alloy and Sapphire Glass for Precision Applications

Vacuum brazing of titanium alloy with sapphire glass is a highly specialized joining technology used in medical devices, optical sensors, aerospace components and high-reliability electronic systems.

Vacuum Brazing Process for Titanium–Sapphire Joints

The brazing process is carried out in a high-temperature vacuum furnace, where an oxygen-free environment prevents oxidation and surface contamination. A carefully selected active brazing alloy, typically containing silver, copper and titanium is placed at the joint interface.

As the furnace reaches the brazing temperature, the filler alloy melts and actively wets both the titanium alloy and the sapphire glass. Upon controlled cooling, a strong, hermetic and mechanically stable bond is formed without damaging the base materials or compromising optical quality.

Advantages of Vacuum Brazing Titanium to Sapphire

Vacuum-brazed titanium sapphire assemblies offer:

clean and contamination-free bonding interfaces

excellent hermetic sealing and leak resistance

minimal thermal stress and distortion

high resistance to temperature, pressure and corrosion

long-term reliability in demanding environments

Applications in High-Performance Industries

Due to its precision and durability, this joining method is widely used in:

medical implants and diagnostic equipment

optical windows and sensor housings

aerospace instrumentation and sealed enclosures

high-vacuum and high-pressure devices

By combining the mechanical strength and corrosion resistance of titanium with the hardness and optical clarity of sapphire glass, vacuum brazing delivers a robust and reliable solution for advanced engineering applications where performance and precision are critical.