Vacuum Brazing of Titanium alloy

Titanium alloy vacuum brazing is a specialized joining process used to manufacture high-performance finished products with excellent strength, cleanliness, and dimensional accuracy. By brazing in a high-vacuum environment, oxidation and contamination are eliminated, allowing precise metallurgical bonding between titanium alloys and compatible filler materials.

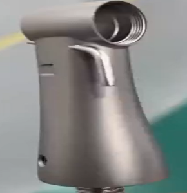

Finished products obtained through titanium vacuum brazing include aerospace structural parts, heat exchanger assemblies, medical and surgical components, chemical processing equipment, and precision industrial fittings. These products exhibit high joint strength, excellent corrosion resistance, and minimal thermal distortion, making them suitable for critical and high-reliability applications.

Overall, vacuum-brazed titanium alloy finished products offer superior performance, long service life, and consistent quality in industries where material integrity and reliability are essential.