Vacuum Brazing of Copper Liquid Cool Plates for India’s Power Electronics Industry

Copper Liquid Cool Plates in India’s Power Electronics Industry

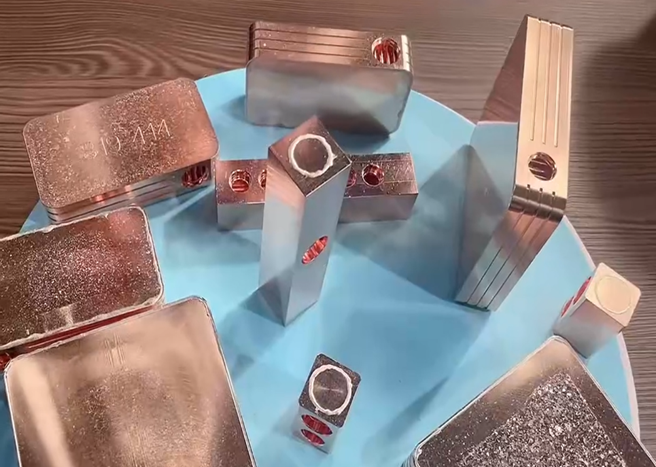

Copper liquid cool plates are essential for thermal management in power electronics modules, including IGBT assemblies (motors, inverters, and converters), SiC devices, thyristors (for high-power AC/DC conversion, rectifiers, and industrial power control), inverters (renewable energy systems, EV chargers, and industrial drives), and data center power systems (UPS units, server power supplies, and cooling systems). Power electronics components need a cooling solution that is both effective and reliable to prevent overheating and ensure stable performance. Efficient liquid cooling significantly improves device reliability and operational life. As India’s power electronics industry expands driven by renewable energy, industrial automation, and data center growth; the demand for high-precision, leak-proof, and high-thermal-conductivity copper liquid cool plates is increasing. Vacuum brazing has become the preferred method for achieving these performance requirements.

Advantages of Vacuum Brazing for Copper Liquid Cool Plates

Vacuum brazing creates strong, oxidation-free, and contamination-free joints, making it ideal for copper liquid cool plate assemblies in power electronics. This method forms a continuous hermetically sealed bond, allowing the plates to withstand high pressure without deformation. It also enables the formation of complex internal flow channel structures, improving heat dissipation and ensuring stable thermal performance. Vacuum brazing furnace delivers highly repeatable results, as each batch achieves accurate vacuum levels and uniform temperature distribution. This ensures reliable and consistent quality for India’s power electronics manufacturers.

Normantherm Vacuum Furnaces for India’s Power Electronics Manufacturers

Normantherm brings over 15 years of expertise in designing and manufacturing advanced vacuum furnace systems for copper liquid cool plate brazing. Our solutions include both horizontal and vertical chamber vacuum furnaces, offering flexibility for various production scales and component sizes. These furnaces deliver precise temperature control, stable vacuum performance, and uniform heating- producing strong, leak-tight, and thermally efficient liquid cool plates for high-power applications. With energy-efficient designs and customizable configurations, Normantherm supports Indian power electronics OEMs in achieving global-standard manufacturing. For companies producing IGBT modules, inverters, and data center power systems, Normantherm provides trusted and industry-ready vacuum brazing technology tailored to India’s rapidly growing power electronics sector.

Editor: Sahera Khatun

Copyright: Normantherm Vacuum Furnace