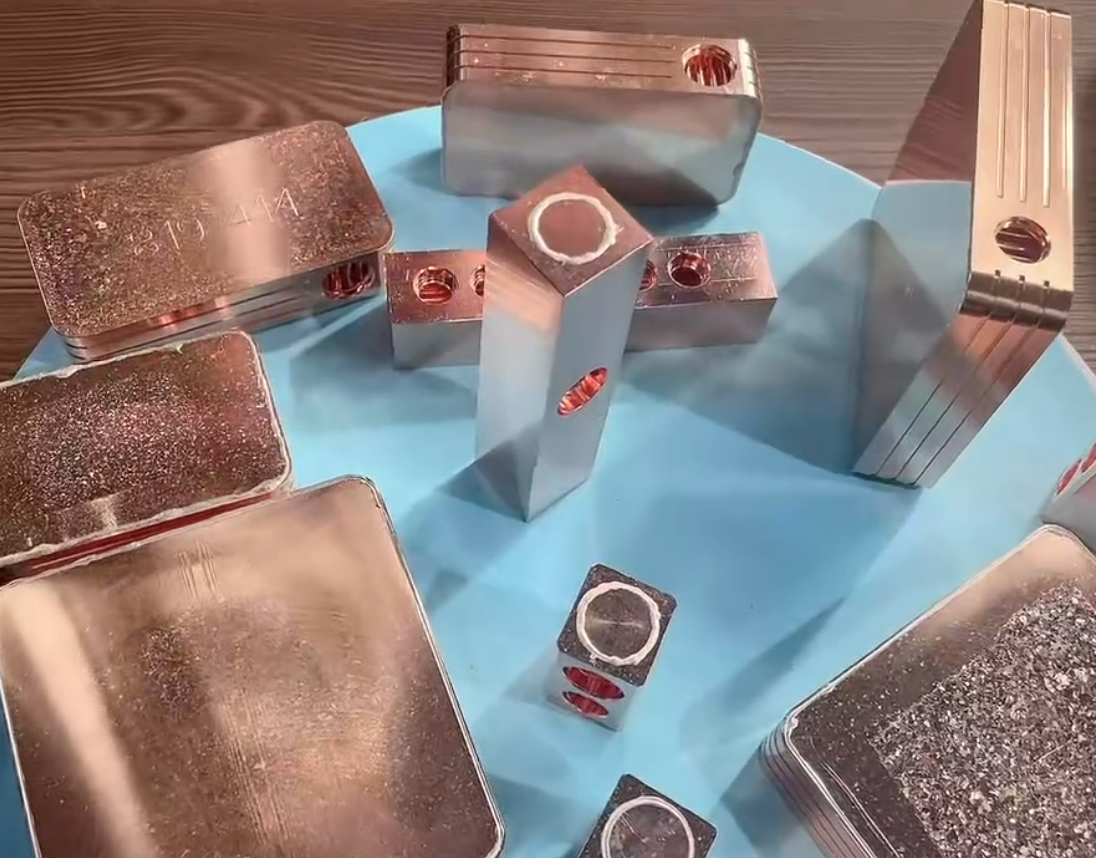

Vacuum-Brazed Copper Water-Cooled Plates for Power Electronics Cooling

As power density in modern electronic and electrical systems continues to rise, effective thermal management has become a critical design factor. From EV inverters and motor drives to industrial power supplies and high-frequency converters, components generate significant heat that must be controlled to ensure efficiency and long-term reliability.

Copper water-cooled plates are one of the most widely used solutions for removing this heat, thanks to copper’s excellent thermal conductivity and the ability to design internal channels for liquid cooling.

The Role of Copper Water-Cooled Plates

Copper water-cooled plates are commonly used in:

- Power electronics modules and IGBT cooling

- EV motor controllers and battery thermal systems

- Industrial drives and high-power rectifiers

- Renewable energy inverters (solar, wind)

These systems often operate continuously and under varying load conditions. A well-designed water-cooled plate ensures that sensitive components stay within safe temperature limits, improving both performance and life expectancy.

Why Vacuum Brazing is Ideal for Cooling Plate Production

To function effectively, these plates require:

- Precisely machined internal flow channels

- Strong, hermetically sealed joints

- Minimal internal contamination or oxidation

Vacuum brazing is the ideal process to achieve these requirements because it:

- Creates clean, flux-free joints inside the cooling passages

- Ensures uniform bond strength over large surface areas

- Minimizes distortion and maintains dimensional accuracy

- Provides leak-tight performance, essential for pressurized coolant systems

Normantherm’s vacuum brazing furnaces are specifically designed to support this type of precision joining.

Normantherm’s Contribution to Power Electronics Cooling

Normantherm delivers advanced vacuum furnace technology used to manufacture high-quality copper water-cooled plates for power electronics and thermal management applications. Our systems offer:

- Stable high-vacuum environments to prevent oxidation

- Accurate temperature control across the entire load

- Compatibility with copper and multi-material brazing

- Consistent results for both prototype development and mass production

For Indian manufacturers in sectors like EV, power electronics, and industrial automation, Normantherm furnaces help upgrade local production capability to global performance standards.

Supporting Indian and Global Industry Growth

With India investing heavily in electric mobility, renewable energy, and high-efficiency industrial systems, demand for reliable cooling technology is increasing. Copper water-cooled plates produced using Normantherm vacuum brazing solutions enable:

- Higher output and efficiency of power modules

- Longer component life due to better thermal control

- Reduced risk of thermal failures in critical applications

By combining engineering expertise and advanced furnace technology, Normantherm supports both Indian and global manufacturers in building more efficient and reliable power systems.

Conclusion

The product display of copper water-cooled plates after brazing is more than a visual of finished parts—it represents the backbone of reliable thermal management in modern power electronics.

With Normantherm vacuum brazing furnaces, manufacturers can confidently produce high-performance cooling plates that meet the tough thermal demands of today’s industrial, EV, and energy systems.