Vacuum Annealing of 316L Stainless Steel Corrugated Pipes for India’s Automobile Manufacturing

Introduction to 316L Stainless Steel Corrugated Pipes in the Automobile Industry

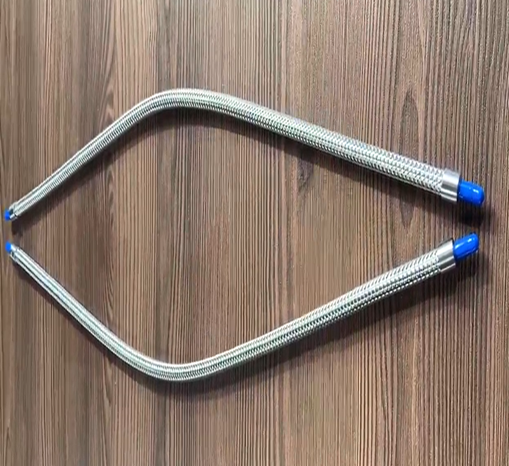

316L stainless steel corrugated pipes are essential components in India’s automobile industry. They are widely used in exhaust flex connectors, EGR and emission-control lines, vibration-damping pipe assemblies, turbocharger connections, and other fluid-transfer applications that demand flexibility and corrosion resistance. These pipes must operate reliably under continuous vibration, temperature fluctuations, and exposure to exhaust gases. However, during the forming and corrugation process, the material becomes work-hardened: leading to increased internal stress and reduced ductility. This can affect long-term performance, making a proper stress-relief process critical for ensuring durability and safety in automotive applications.

Advantages of Vacuum Annealing for 316L Stainless Steel Corrugated Pipes

Vacuum annealing is the most reliable method for restoring the optimal microstructure of 316L stainless steel corrugated pipes. The vacuum annealing process is performed in an oxygen-free environment, which prevents oxidation and scaling and ensures a bright, clean surface without requiring additional surface treatment. It effectively reduces hardness, relieves internal stresses, improves ductility, and enhances overall formability- key benefits for thin-wall corrugated tubes that must withstand vibration, bending, and thermal cycles. For Indian automobile manufacturers striving for higher fatigue life, consistent quality, and global-standard performance, vacuum annealing ensures superior metallurgical stability and long-term reliability.

Vacuum Furnace Solutions for Vacuum Annealing of 316L Stainless Steel Corrugated Pipes in India

Normantherm, with over 15 years of expertise in vacuum furnace technology, provides advanced solutions for vacuum annealing of 316L stainless steel corrugated pipes. Our furnaces deliver precise temperature control, strong vacuum performance, and uniform heating, enabling manufacturers to achieve repeatable, oxidation-free results suitable for large-volume production. By leveraging Normantherm’s proven expertise, automotive component producers can significantly reduce rework, extend product life, and meet international standards with confidence.

Editor: Sahera Khatun

Copyright: Normantherm Vacuum Furnace