Titanium Alloy Welding with Sapphire Glass for the Medical Optics & Endoscope Industry

In modern medical optics and endoscope technology, components must withstand tough conditions: repeated sterilization, mechanical stress, moisture, body fluids, and high-temperature cleaning cycles. At the same time, they must offer exceptional optical clarity, reliability, and safety for patients.

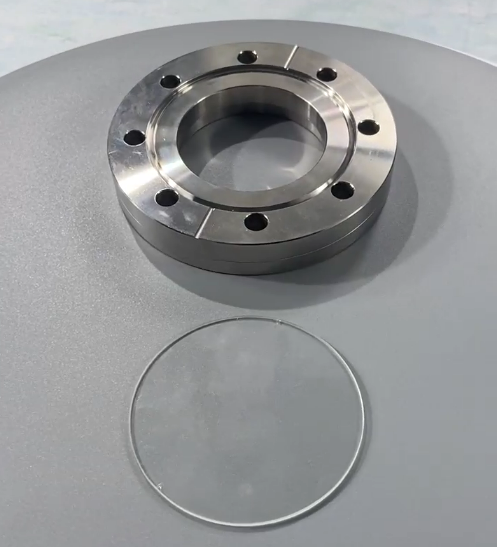

One advanced solution is the joining of titanium alloy with sapphire glass, a combination that is increasingly used in endoscopes, medical imaging windows, and minimally invasive surgical tools.

Normantherm’s vacuum furnace technology plays a key role in making these complex assemblies possible.

Why Titanium Alloy and Sapphire Glass?

Titanium alloys are widely used in the medical industry due to their:

- High strength-to-weight ratio

- Excellent corrosion resistance

- Biocompatibility

- Suitability for long-term contact with the human body

Sapphire glass (single-crystal aluminum oxide) is valued for:

- High hardness and scratch resistance

- Excellent optical clarity

- High temperature and chemical resistance

- Durability in harsh cleaning and sterilization environments

When combined, titanium and sapphire glass create a robust, biocompatible, and optically reliable structure that is ideal for endoscope windows, protective optical covers, and medical imaging components.

Role of Vacuum Brazing / Welding in Titanium–Sapphire Assemblies

Joining titanium alloy and sapphire glass is technically challenging. The materials have very different properties and thermal behavior, so ordinary welding methods are not suitable.

This is where vacuum brazing and specialized joining processes become essential.

Using a Normantherm vacuum furnace, manufacturers can:

- Create strong, hermetic joints between titanium and sapphire glass

- Carefully manage temperature profiles to minimize thermal stress

- Maintain a clean, oxidation-free interface, essential for bond strength and optical quality

- Achieve repeatable results for mass production or high-value batches

The vacuum environment protects both titanium and sapphire from oxidation, contamination, and unwanted chemical reactions during heating.

Normantherm’s Contribution to the Medical Optics Industry

Normantherm supplies advanced vacuum furnace systems designed for complex joining and heat treatment tasks, including titanium alloy welding and brazing with sapphire glass.

For medical optics and endoscope manufacturers, our systems offer:

- Precise temperature control and uniformity for sensitive assemblies

- High vacuum levels to ensure clean bonding surfaces

- Flexible process programs for different titanium grades and sapphire geometries

- Compatibility with other metal–ceramic and metal–glass combinations used in medical devices

This enables customers to produce components that meet the stringent demands of hospital, surgical, and diagnostic environments.

Relevance for Indian Medical Device Manufacturers

India is steadily building its presence in the medical device and healthcare equipment sector, including areas such as:

- Endoscope manufacturing and assembly

- Diagnostic equipment and imaging systems

- Minimally invasive surgical tools

- OEM and contract manufacturing for global brands

To be competitive in global supply chains, Indian manufacturers must deliver components with consistent quality, long-term reliability, and compliance with international standards.

Normantherm supports Indian medical device manufacturers by:

- Providing vacuum furnace solutions suitable for titanium–sapphire glass assemblies and other advanced joints

- Helping improve process stability and joint reliability

- Supporting R&D and production needs for high-end medical optics and instruments

By adopting Normantherm technology, Indian companies can strengthen their capability in premium medical optics, endoscopes, and precision assemblies for both domestic and export markets.

Conclusion

The titanium alloy welding with sapphire glass showcased in the video is an example of how advanced vacuum technology enables high-performance medical optical components.

With Normantherm vacuum furnaces, manufacturers can achieve clean, strong, and reliable joints between titanium and sapphire glass, ensuring that endoscopes and medical imaging tools perform safely and consistently in demanding clinical environments.