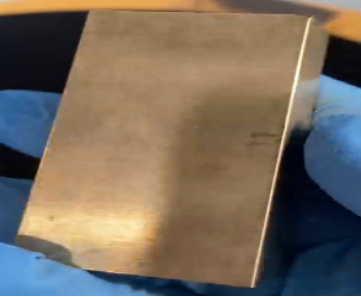

Heat Treatment of Brass for Improved Strength, Ductility and Workability

Heat treatment of brass is an important metallurgical process used to improve the mechanical and structural properties of brass alloys, which are mainly composed of copper and zinc. This process is commonly applied to restore material softness after cold working, relieve internal stresses and enhance overall formability and performance.

Annealing and Stress Relief of Brass

The most widely used heat treatment for brass is annealing. In this process, brass components are heated to a controlled temperature range of 450°C to 650°C, held for a specific duration, and then slowly cooled. Annealing softens the material, improves ductility and makes brass easier to bend, draw, stamp or machine without the risk of cracking.

For components that do not require full softening, stress relieving is carried out at lower temperatures. This treatment removes residual stresses generated during machining, forming or fabrication while maintaining dimensional stability and mechanical integrity.

Benefits of Proper Brass Heat Treatment

Correct heat treatment of brass offers several advantages:

improved ductility and workability

reduced internal stress and distortion

consistent dimensions and surface quality

enhanced corrosion resistance

extended service life

Applications of Heat-Treated Brass Components

Heat-treated brass is widely used in:

electrical fittings and connectors

valves and plumbing components

musical instruments

precision machined parts

decorative and architectural hardware

By applying controlled annealing and stress-relief processes, brass components achieve the required balance of strength, formability and appearance, making heat treatment a critical step in high-quality brass manufacturing.