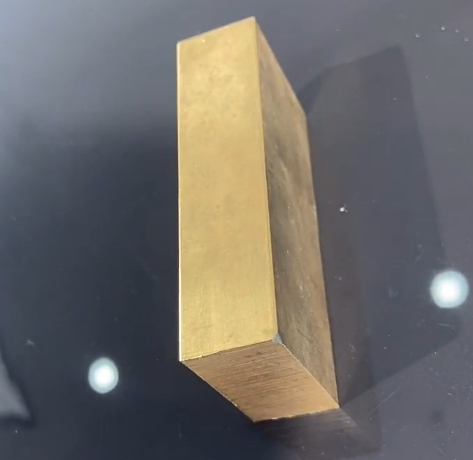

Heat-Treated Brass for Reliable Electronic Components

In the electronics industry, brass is widely used for connectors, terminals, and conductive parts, where both mechanical stability and corrosion resistance are essential. However, untreated brass may suffer from internal stress, surface oxidation, or dimensional instability, leading to performance issues over time.

Normantherm provides precision heat treatment solutions tailored to brass alloys, using vacuum furnace technology to perform stress relief, annealing, and hardness conditioning without surface discoloration or oxidation.

Key advantages of Normantherm’s vacuum brass treatment include:

- Improved electrical conductivity stability

- Oxidation-free surfaces ideal for plating or coating

- Enhanced machinability and deformation resistance

- Reliable performance under thermal and mechanical load

By combining industrial expertise with advanced vacuum systems, Normantherm ensures that brass components used in electronic connectors, relays, and PCB assemblies meet the highest reliability standards — ready for long-term use in sensitive circuits.