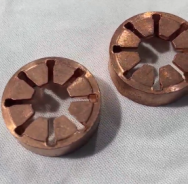

Advanced Vacuum Brazing of Graphite to Purple Copper(T2)

Graphite and purple copper(T2) are frequently combined in high performance engineering components like electrodes, heat exchangers and nuclear fusion components. While purple copper offers good mechanical strength and superior thermal and electrical conductivity, graphite offers exceptional thermal stability, self-lubrication, and electrical conductivity.

However, it is difficult to join these two dissimilar materials with traditional joining methods. Particularly for precision and high temperature applications, vacuum brazing with active fillers has become a dependable way to create high strength, contamination free joints between graphite and copper.

Material Properties

Graphite

Graphite is a carbon-based material with good thermal and electrical conductivity, a low coefficient of thermal expansion, and outstanding thermal stability. Additionally, it has strong chemical inertness and self-lubricating behavior, which make it appropriate for harsh and high-temperature environments. However, graphite's poor wettability with molten metals due to its non-metallic and porous nature makes conventional joining challenging without the use of active brazing techniques.

Purple copper (Pure copper)

Purple copper, also known as high-purity copper, is used extensively due to its exceptional electrical and thermal conductivity, as well as its good ductility and resistance to corrosion. Under vacuum, where oxidation is reduced, it brazes effectively. However, because of its much greater thermal expansion than graphite, residual stresses may be introduced during the process but this typical problem can be significantly reduced through controlled vacuum brazing and appropriate filler metal selection.

Technical Challenges in Graphite-Copper Brazing

There are various technical difficulties when joining graphite and Cu:

§ Graphite's poor wettability with molten copper

§ Weak interfacial bonding without proper filler materials

§ Risk of copper infiltration into graphite pores

§ Mismatch in thermal expansion, resulting in residual stress

CTE: Graphite![]()

CTE: Pure Copper![]()

Proper material selection, surface treatment, and optimized brazing parameters are necessary to overcome these obstacles.

The Metallurgy of Active Brazing

To bond a metal to a non-metal, the filler material must undergo a chemical reaction with the substrate. This is known as Active Brazing. To improve wettability and bonding strength, active brazing alloys are commonly used. The most successful filler materials for this application are Silver-Copper-Titanium (Ag-Cu-Ti) alloys. Titanium is the "active" element. During the vacuum heating process, Titanium atoms migrate to the graphite interface.

The Reaction Layer

Titanium reacts with the carbon atoms in the graphite to form a microscopic layer of Titanium Carbide (), At temperature between .

This layer transforms the graphite surface from a non-wetting ceramic-like state to a metallic state, allowing the Ag-Cu eutectic liquid to spread and bond.

Optimized Process Parameters

To ensure a successful joint, the following vacuum brazing parameters are recommended:

Parameter | Recommended Setting |

Vacuum Level |

|

Filler Material | Ag72Cu28Ti (2 - 4% Ti) |

Brazing Temp | 850°C to 1050°C |

Holding Time | 10–20 minutes |

Cooling Rate | < 5°C / minute (to room temp) |

Why the Vacuum Brazing is Preferred

The use of a vacuum Brazing furnace (typically operating at ) is preferred for three primary reasons: Chemical Protection, Physical Cleanliness, and Thermal Precision.

ü Protection of the Active Element (Titanium)

The most critical reason for using a vacuum is the behavior of Titanium. Titanium is a powerful "oxygen getter," meaning it will react with even trace amounts of oxygen or nitrogen to form stable oxides or nitrides. That’s why absence of air is necessary.

ü Flux-Free Joining

Graphite is naturally porous so the use of chemical fluxes can seep into the graphite structure, causing internal corrosion or "outgassing" issues later in the component's life. The vacuum environment itself acts as the cleaning agent by decomposing surface oxides on the purple copper, resulting in a joint with zero chemical residue.

ü Uniform Heating and Stress Control

Due to the CTE mismatch, thermal stress is the enemy of a graphite-Cu bond.

A vacuum furnace heats through radiation, ensuring the entire assembly reaches the target temperature simultaneously. This prevents local "hot spots" that would occur with a torch, which would cause uneven expansion and immediate cracking of the graphite.

Vacuum furnaces allow for highly precise, programmed cooling ramps. This allows the purple copper to slowly relax and the filler metal to solidify evenly, significantly reducing the residual stress trapped in the joint.

ü Degassing of the Graphite

Moisture and trapped gases are naturally present in the pores of graphite. These gases would expand and produce "blowholes" or voids in the braze joint if heated in a typical atmosphere. Before the filler metal melts, the vacuum environment extracts these gases from the graphite (degassing), guaranteeing a dense, void-free metallurgical bond.

Performance Indicators of Vacuum Brazing Furnace

VF Series (Horizontal Type)

| Models | Effective Hot Zone Size(L*W*H), mm | Heating Power, Kw | Ultimate Vacuum, Pa | Pressure Rising Rate | MAX Temp., | Temp. Uniformity, |

| VF1300-222 | 200×200×200 | 28 | ≤1 Pa/h | ±5 | ||

| VF1300-422 | 400×200×200 | 32 | ≤1 Pa/h | ±5 | ||

| VF1300-644 | 600×400×400 | 60 | ≤1 Pa/h | ±5 | ||

| VF1300-755 | 700×500×500 | 120 | ≤1 Pa/h | ±5 | ||

| VF1300-966 | 900×600×600 | 150 | ≤1 Pa/h | ±5 |

CUT Series (Vertical/Tubular Type)

| Models | Tube Dia., mm | Tube Length, mm | Heat zone, mm | Power, Kw | Ultimate Vacuum, Pa | Max. Temp, |

| CUT200 | 200/190 | 600 | 400 | 18 | 1000 | |

| CUT250 | 250/240 | 600 | 400 | 24 | 1000 |

TF series (Horizontal/Tubular Type)

| Models | Tube Dia., mm | Tube Length, mm | Heat zone, mm | Power, Kw | Ultimate Vacuum, Pa | Max. Temp, |

| TF1000-200-HV-SL-T10 | 200 | 1400 | 400 | 10.8 | 1000 | |

| TF1000-250-HV-SL-T10 | 250 | 1400 | 400 | 10.8 | 1000 | |

| TF1000-100-HV-T7 | 100 | 900 | 400 | 4.8 | 1000 | |

| TF1000-200-HV-T10 | 200 | 1100 | 600 | 18 | 1000 | |

| TF1000-250HV-T10 | 250 | 900 | 400 | 10.8 | 1000 |

Conclusion

An efficient and commercially successful technique for joining graphite and purple copper is vacuum brazing. High-strength and high-performance joints can be produced by employing active brazing alloys, exact vacuum control, and optimized process parameters. Graphite-copper vacuum brazing will become more crucial in contemporary manufacturing as sophisticated thermal and electronic applications continue to expand.