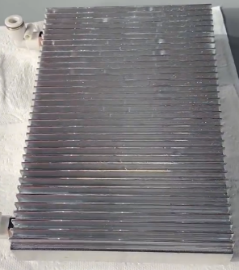

6063 Series Aluminum Finned Heat Exchangers

Known for its excellent surface finish, corrosion resistance and thermal conductivity, 6063 aluminum is especially well suited for complex finned structures. When combined with vacuum brazing, it delivers a high-performance and long-lasting thermal management solution.

Vacuum Brazing as a Finishing Process

Vacuum brazing is the key finishing process that transforms individual fins, tubes and headers into a single, high-integrity heat exchanger core. Compared to mechanical fastening or conventional welding, vacuum brazing provides superior joint quality and consistency, making it the preferred method for critical heat exchanger applications.

During vacuum brazing, the assembled 6063 aluminum components are placed in a controlled vacuum furnace with a suitable brazing filler material. The oxygen-free environment prevents oxidation and eliminates the need for flux, resulting in clean, strong and leak-proof joints throughout the heat exchanger.

High-Performance Thermal Management Solution

The combination of easily extrudable, corrosion-resistant 6063 aluminum alloy and the clean, robust finish achieved through vacuum brazing results in finned heat exchangers optimized for demanding thermal environments. These heat exchangers deliver consistent performance, high efficiency and extended service life in applications where reliable heat dissipation is critical.